- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Bricsys BricsCAD® Software

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

UltiMaker S-Series PVA Natural 350g Filament (9732)

-

Description

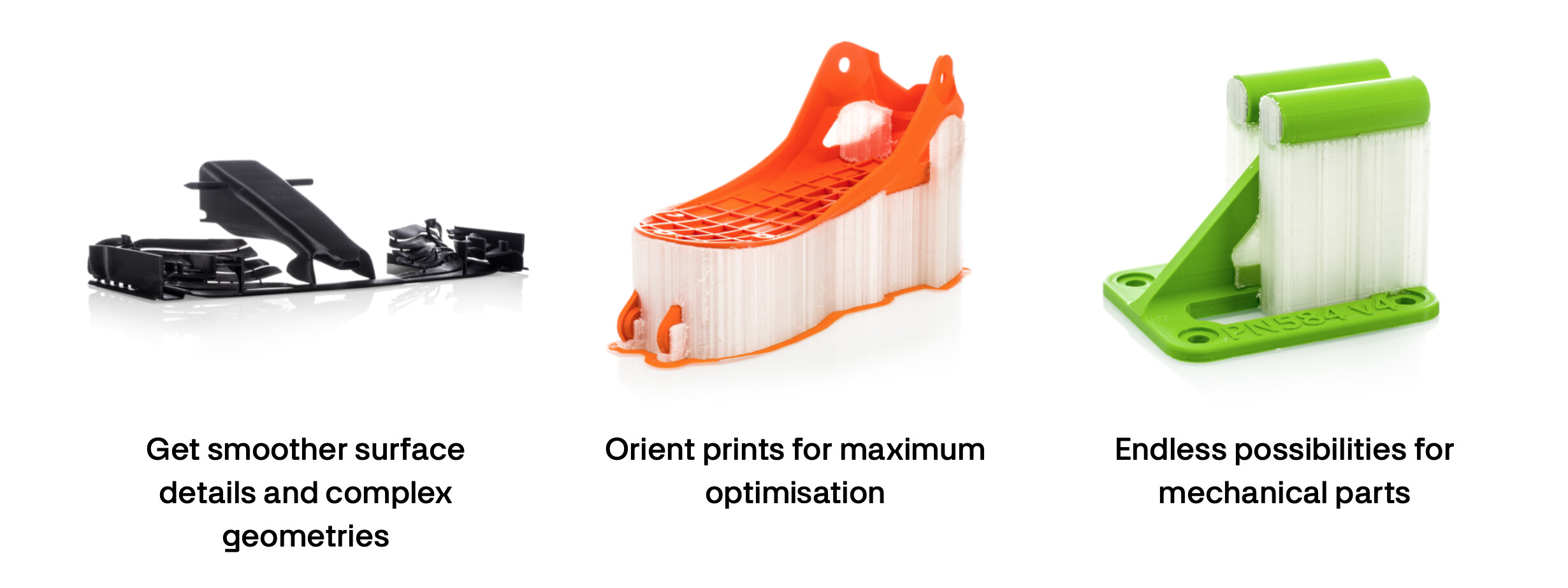

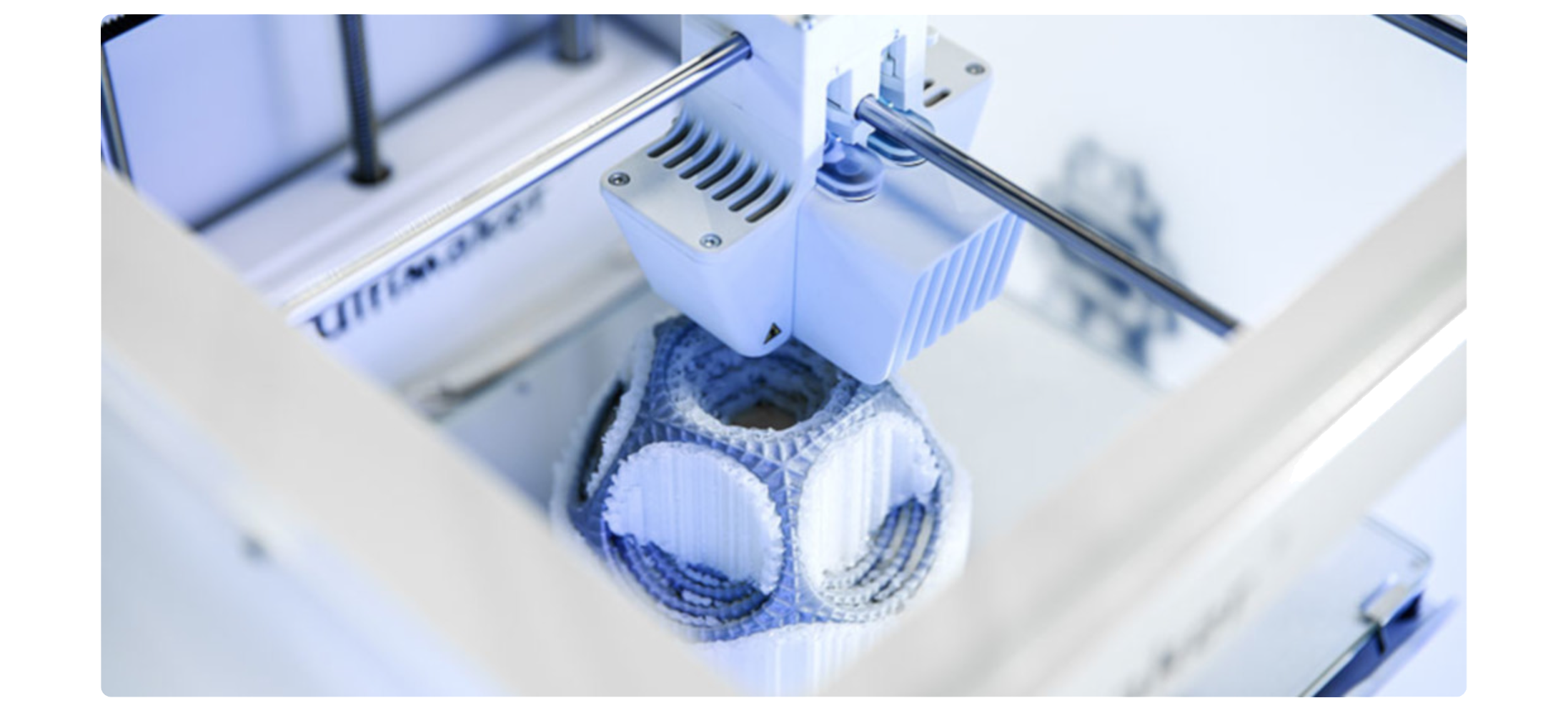

UltiMaker S-Series PVA Natural 350g Filament (9732): A water-soluble support material specifically engineered for multi-extrusion 3D printing. With excellent thermal stability, UltiMaker PVA is perfect for printing intricate models with large overhangs, deep internal structures, and complex geometries. Crafted to seamlessly integrate into your 3D printing workflow, UltiMaker PVA adheres well to a variety of filaments including PLA, ABS, PETG, and TPU, ensuring hassle-free printing.

Unlike supports printed with build material, PVA 3D printing support structures reduce the chance of scraping and cutting marks on detailed surfaces. Preparing a print with PVA gives you the freedom to orient your model in any way possible to customise its strength or aesthetic properties. Multi-component applications such as ball bearings, ball and socket joints, and caged gear mechanisms can be 3D printed as a complete assembly in a single run.

Experience quicker and easier post-processing when using PVA support material for complex parts or stunning visual prototypes, with the Ultimaker PVA Removal Station. Part of UltiMaker's start-to-finish 3D printing platform, it ensures quicker design iterations with minimal operator time and no mess. Please refer to the PVA Removal Station tab for more infos.

KEY FEATURES:

- Good thermal stability resulting in better degradation resistance compared to other PVA filaments

- Less moisture sensitive than other PVA filaments

- Great adhesion to both PLA and Nylon

- Safe dissolution in tap water (no harmful chemicals required); biodegradable with no hazardous by-products

APPLICATIONS:

- Reliable 3D printing of water soluble support structures for PLA and Nylon build materials

- PVA moulds

-

Other available sizes

-

How to store PVA material

PVA support material is used for 3D printing objects with complex geometries, cavities, or overhangs. PVA supports a model’s shape while it is 3D printed, then dissolves away in water. But as its chemistry makes it sensitive to moisture, its quality can reduce over time in storage. We look at some of the ways you can store and care for your PVA material to get the best results.

Ultimaker PVA material is formulated to be less moisture-sensitive than other PVA filaments, but it still helps to look after it in the right way.

HOW TO STORE PVA SPOOLS:

Storing your PVA in optimal conditions is key to a high-quality 3D print. If stored improperly, PVA can absorb ambient moisture (you will notice it becomes soft, pliable, and maybe even sticky) or become too dry (making it brittle), both potentially causing extrusion problems and loss of print quality.

If moisture is the problem, you may see bubbles in your PVA filament caused by the moisture and notice a popping sound when printing. Print quality will be reduced, with bad layers of PVA support likely to cause failed prints. This could also lead to your BB print core becoming clogged.

One of the best ways to avoid any problems is to keep your PVA in a sealed container when you are not using it. If you have Ultimaker PVA, we recommend reusing the resealable bag and desiccant included in the original packaging as a starting point. This should be enough to keep your material in good condition.

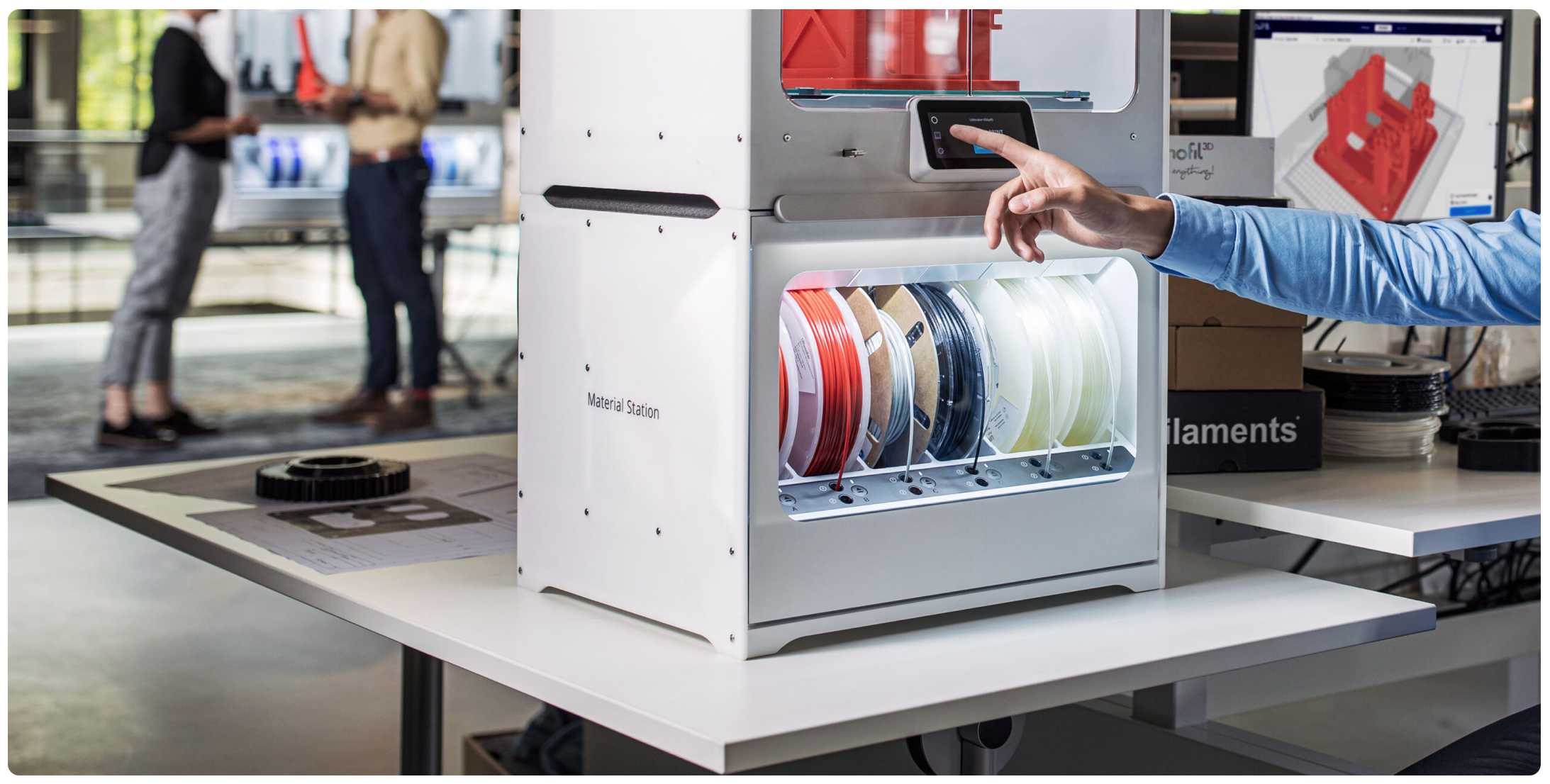

If you use PVA frequently with the Ultimaker S7/S5, the Material Station accessory offers a unique solution for storing materials in optimal conditions. Its six-spool capacity chamber controls the environment to keep relative humidity below 40% at all times. So there's no need for DIY dry boxes as well as less time spent operating the printer.

Ultimaker S7/S5 Material Station composite-ready prefeeder Ultimaker S7/S5 Material Station loaded with PVA and other materials Some third-party manufacturers provide other solutions, such as specialist filament storage boxes, or you can use another type of air-tight container you may have to hand.

The optimal temperature for storing PVA is between 0 °C and 30 °C, and recommended relative humidity for your storage area is below 50%. We also recommend you keep it out of sunlight.

WHAT IF YOUR PVA LOSES QUALITY?

If your PVA does absorb moisture, it is still possible to dry it out again.

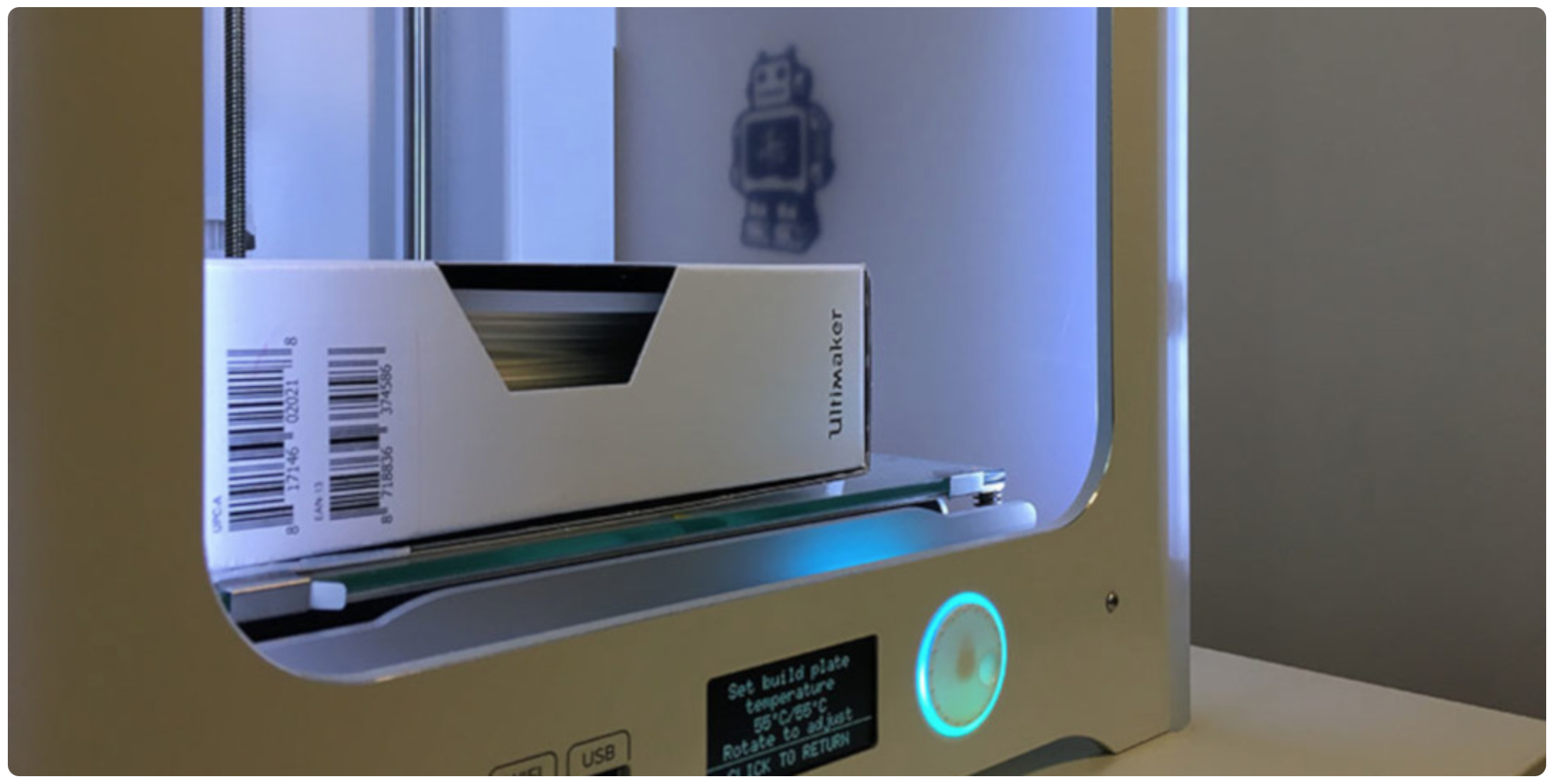

PVA on build plate PVA filament drying on the Ultimaker 3 build plate The easiest way to dry the filament is with your Ultimaker 3D printer’s heated build plate. Place the spool inside a cardboard box (for example an Ultimaker filament box) and on the build plate, heat it up to 55 °C, and wait for a few hours while the filament dries.

-

UltiMaker PVA Removal Station

A rinsing basket keeps your print in place and completely submerged while dissolving, then lifts up for mess-free draining and print removal.

MAIN FEATURES:

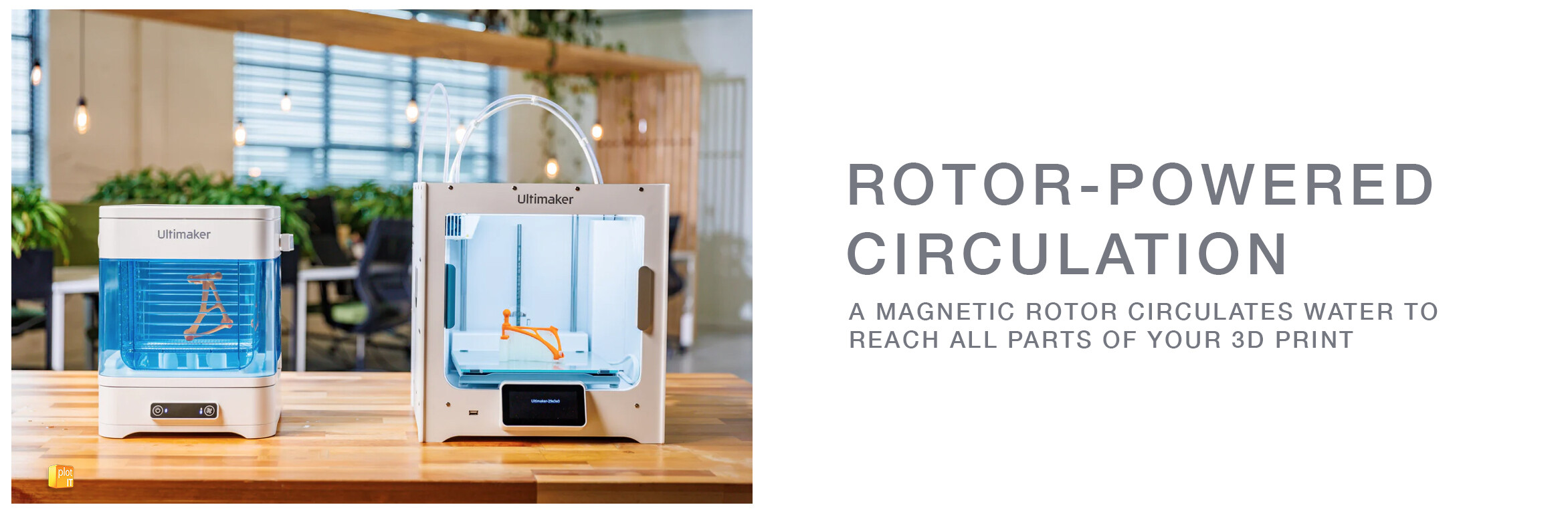

- ROTOR-POWERED CIRCULATION: A magnetic rotor circulates water to reach all parts of your 3D print

- ADJUSTABLE ROTOR SPEED: Adjust for faster dissolving or to protect fragile parts

- KEEPS PRINTS SECURED: A rinsing basket keeps prints in place and submerged

- EASY TO FOLLOW PROGRESS: A transparent, illuminated container makes it easy to know exactly when your part is ready

- LOW MAINTENANCE: Ergonomically designed for easy cleaning

- NO CHEMICALS NEEDED: Just fill with regular tap water, which can be safely disposed of when finished

- CLEAN & NO MESS: Ergonomic design features help keep your workspace clean and tidy

A transparent, illuminated container lets you easily follow the PVA removal process and see when your part is ready. Plus, a saturation indicator shows when to refresh the water.

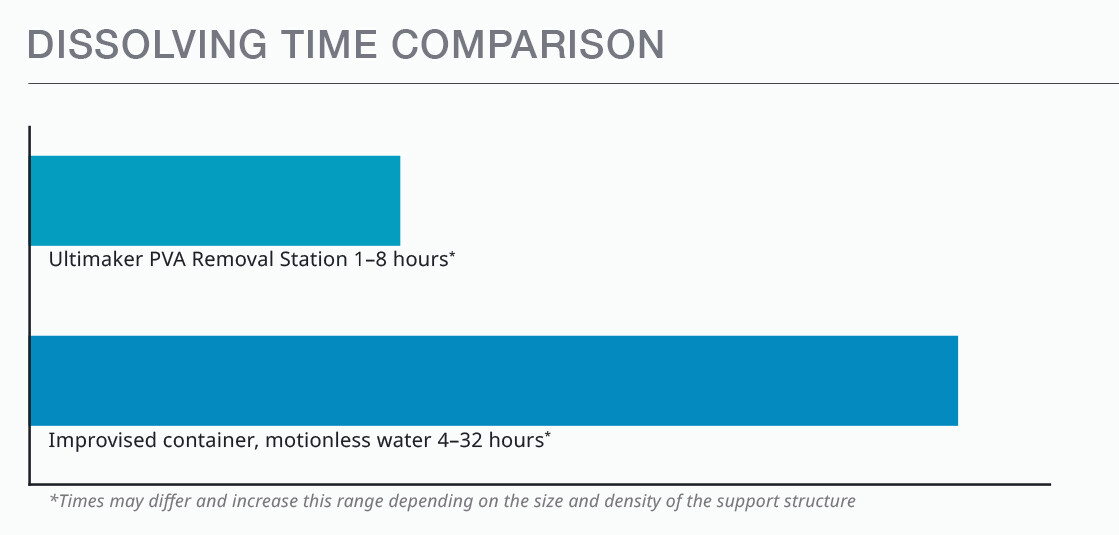

The Ultimaker PVA Removal Station features a high-speed dissolving process driven by a magnetic rotor. Compared with motionless water in an improvised container, it removes PVA up to four times faster – even from hard-to-reach cavities in complex designs. So you have parts ready as soon as possible.

The PVA Removal Station requires only a few minutes of operator time per print, and almost zero maintenance. Just press the start button. Leave it to spin. And collect your print when it’s ready.

Choose 100 or 225 RPM circulation depending on the fragility of your part. Every two minutes, the rotor changes direction to push water evenly against the model. A rinsing basket keeps your print in place and completely submerged while dissolving, then lifts up for mess-free draining and print removal.