- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Bricsys BricsCAD® Software

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

UltiMaker S8 3D Printer (64-237331)

Click the yellow arrows to view multiple buying options...

- Description

- Consumables

- Optional Material Station

- Optional PVA Removal Station

- Tech specs & Comparison Chart

- Training

-

Description

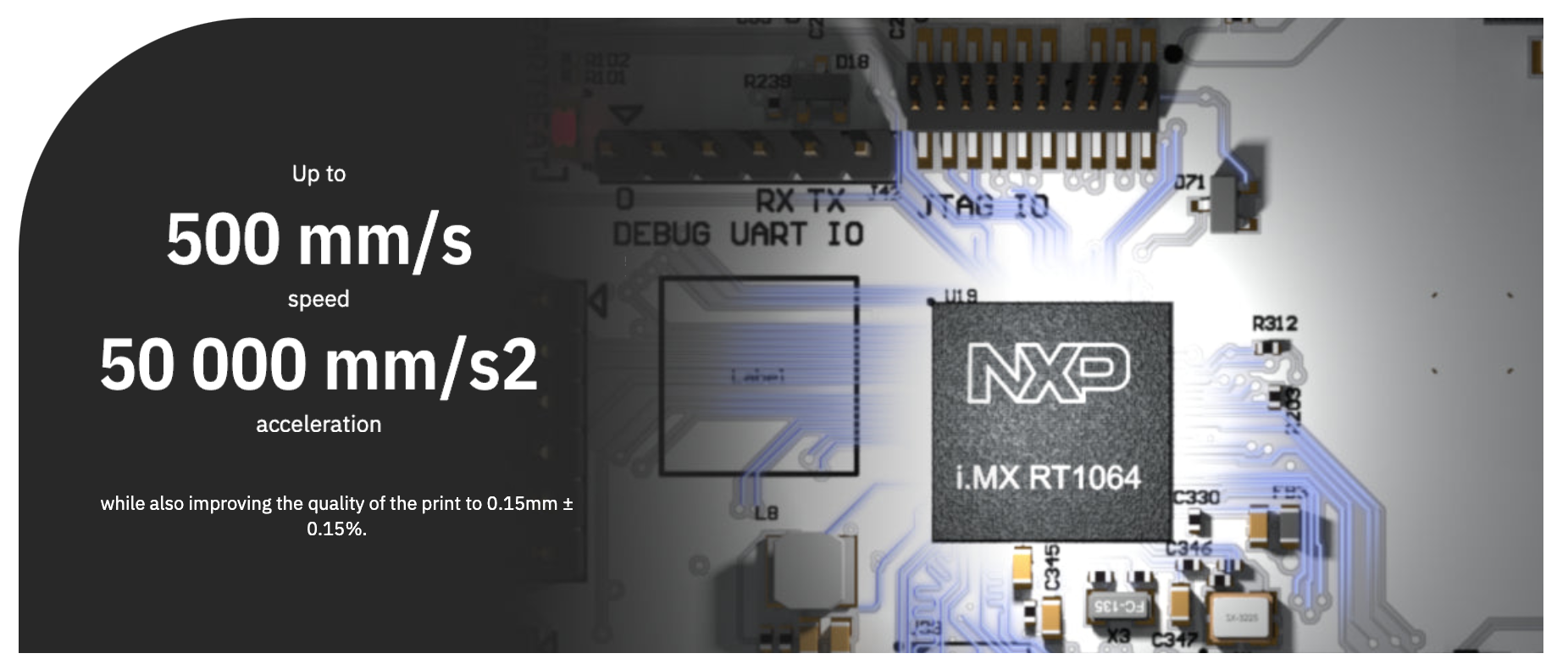

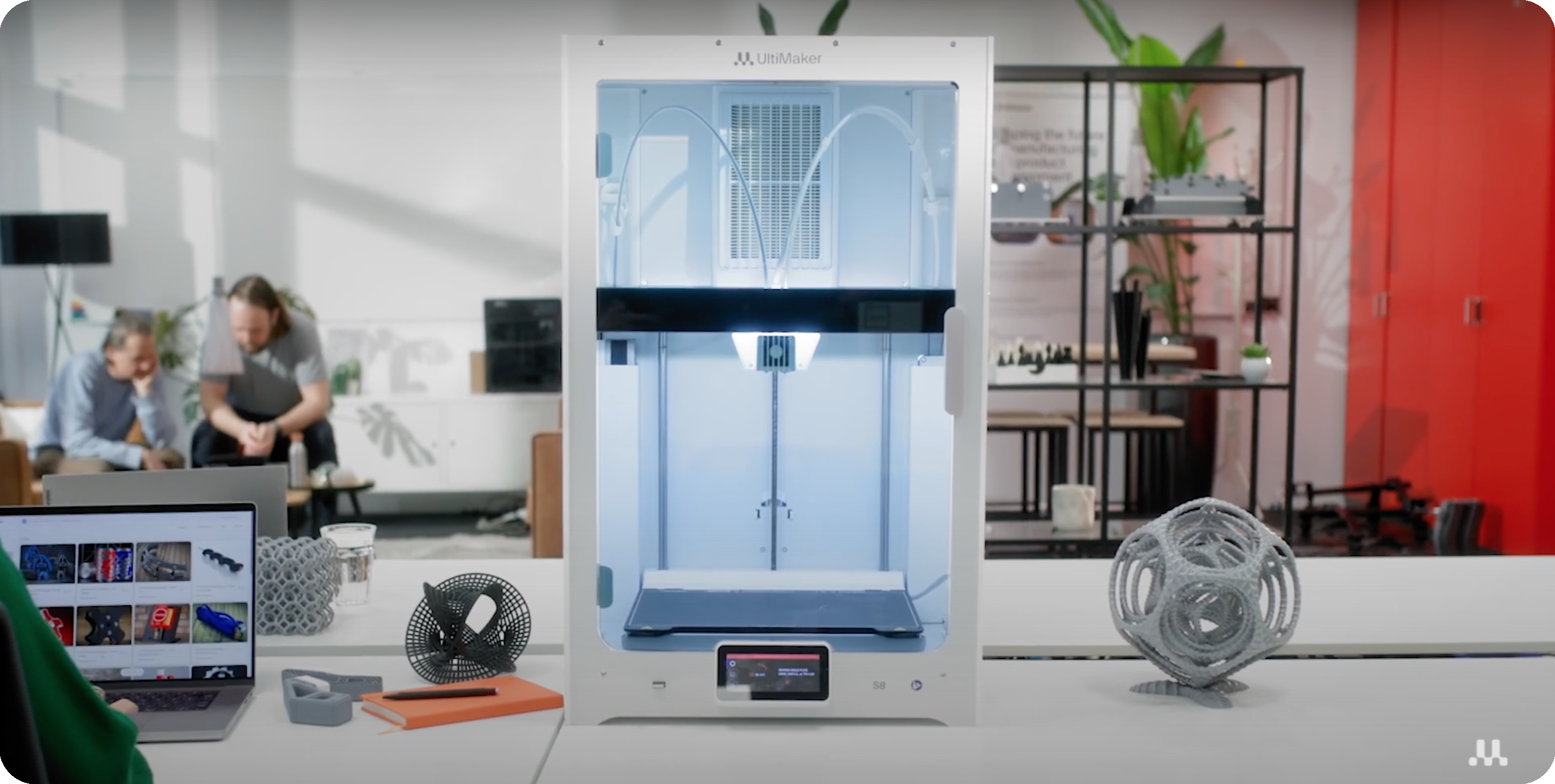

UltiMaker S8 3D Printer (64-237331): Represents a significant leap forward in additive manufacturing technology. Designed to meet the demands of modern production environments, it offers unparalleled speed and precision. Capable of reaching print speeds up to 500mm/s and accelerations up to 50,000mm/s², the S8 delivers up to four times the productivity of its predecessors. This remarkable performance is achieved without compromising on print quality, making it an ideal solution for businesses requiring rapid turnaround times.

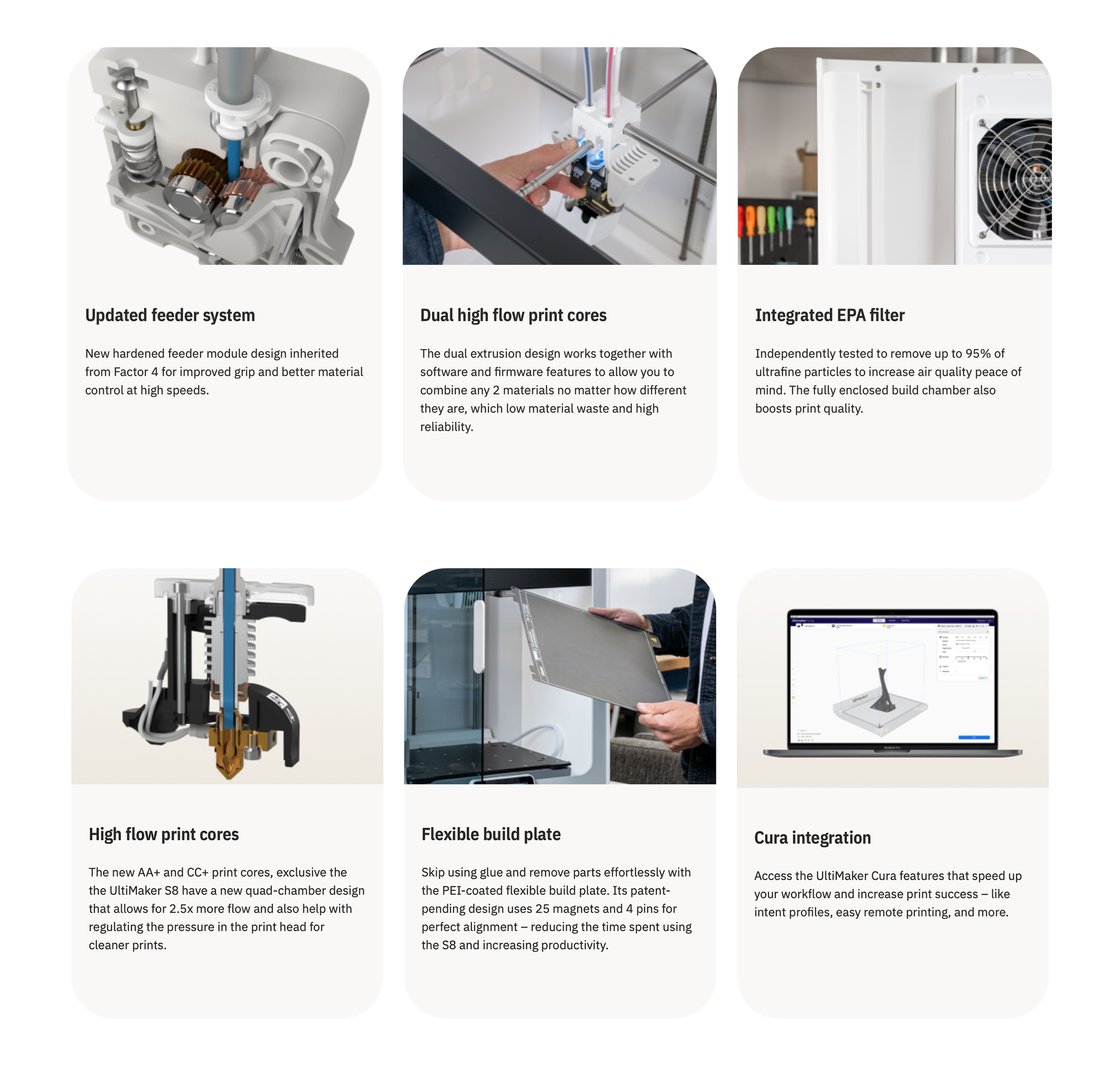

Central to the S8's performance is the UltiMaker Cheetah motion planner, which enhances motion control for precise movements. This innovation ensures a precision of 0.15mm ± 0.15%, effectively eliminating common issues such as ringing and blobs that can occur at high speeds. Complementing this is the inclusion of high-flow AA+ and CC+ print cores, delivering 2.5 times more material flow compared to previous models. These advancements contribute to both efficiency and quality, particularly when working with composite and engineering-grade materials.

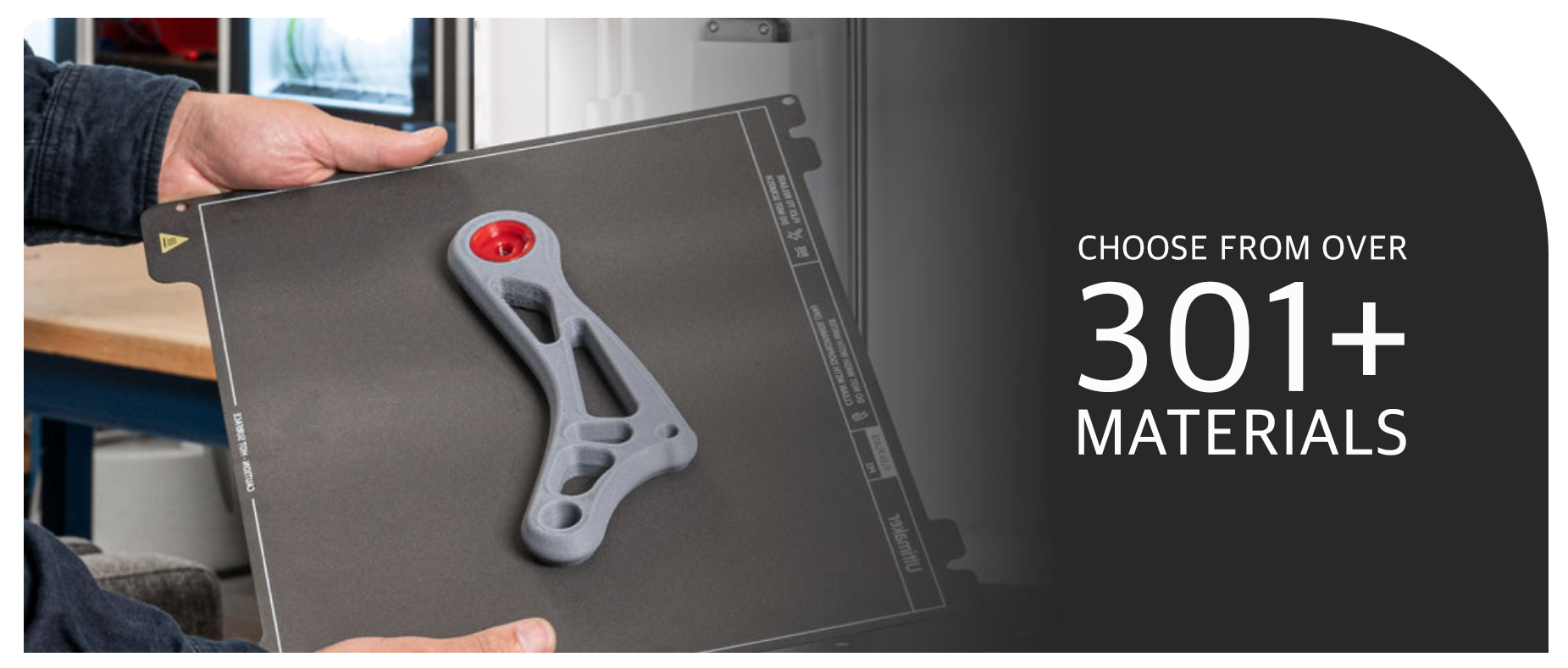

The S8's versatility is further highlighted by its dual-material printing capabilities, allowing for the creation of complex parts using multiple materials in a single print job. Compatibility with UltiMaker's extensive material marketplace, offering over 300 materials, provides users with the flexibility to experiment and select the best material for their specific applications. Notably, the new UltiMaker Nylon CF Slide, a Nylon 612 CF copolymer, offers excellent wear resistance and temperature stability up to 180°C, making it ideal for industrial applications where tribological performance is crucial.

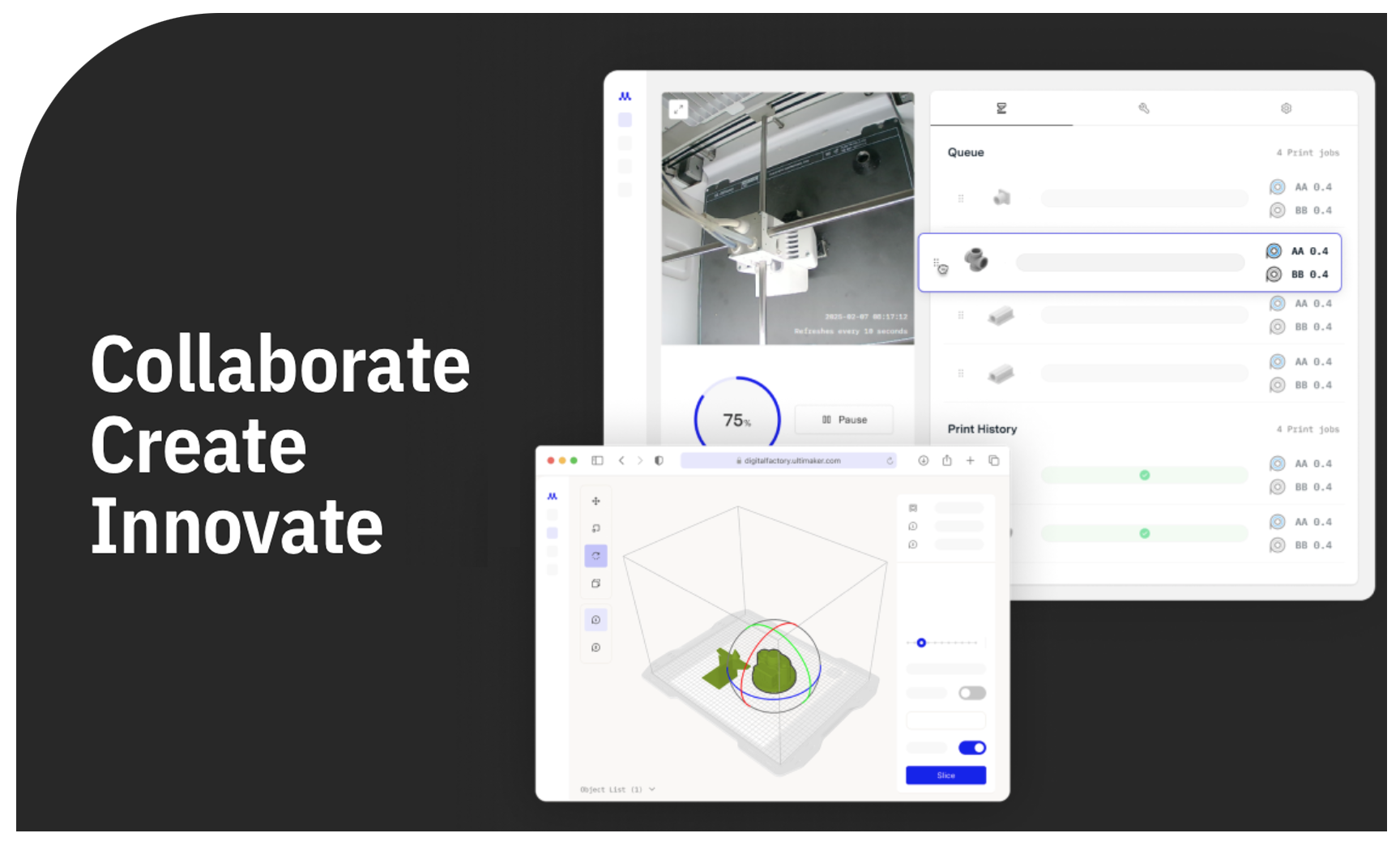

Integration with UltiMaker's Digital Factory and the newly introduced Cura Cloud slicer streamlines the 3D printing workflow. Users can now slice, manage, and print from a single platform, enhancing efficiency and collaboration across teams and time zones. The S8's compatibility with various operating systems, including macOS, Windows, and Linux, ensures a seamless user experience. Additionally, the printer supports a wide range of file formats such as STL, OBJ, X3D, and 3MF, catering to diverse user needs.

Digital Factory also offers a variety of subscription plans, allowing users to customise their options based on production needs. Whether creating prototypes or production-ready components, the S8 provides unmatched flexibility in the professional 3D printing market.

The expansion of Cura from desktop to cloud makes this powerful slicer accessible to all Digital Factory users. Additionally, the latest Cura 5.10 beta release includes optimised print and material profile settings to further streamline the process. Compatibility with the UltiMaker Marketplace also provides users the freedom to experiment with their choice of materials.

Built with future-proofing in mind, the S8 features a completely revamped electronics platform, offering five times the processing power of its predecessor. This significant upgrade ensures the printer can handle the demands of the advanced motion planner and supports future updates, securing long-term productivity. The robust design and enhanced processing capabilities make the S8 a reliable choice for businesses looking to invest in durable and efficient 3D printing technology.

The UltiMaker S8 3D printer features an integrated EPA filter, designed to enhance air quality during operation by removing up to 95% of ultrafine particles.

KEY FEATURES:

- ENHANCED PRODUCTIVITY: Achieves up to 4 times faster print speeds compared to previous models.

- ADVANCED MOTION CONTROL: Features the UltiMaker Cheetah motion planner for precise movements and high-quality prints.

- HIGH-FLOW PRINT CORES: Equipped with AA+ and CC+ print cores, delivering 2.5 times more material flow.

- ROBUST FEEDER SYSTEM: Newly designed hardened feeder module ensures reliable material handling at high speeds.

- DUAL-MATERIAL PRINTING: Supports dual extrusion, allowing for complex parts with multiple materials in a single print job.

- SEAMLESS SOFTWARE INTEGRATION: Compatible with UltiMaker Digital Factory and Cura Cloud for streamlined workflows.

- EXTENSIVE MATERIAL COMPATIBILITY: Access to over 300 materials, including the new UltiMaker Nylon CF Slide.

- FUTURE-PROOF DESIGN: Powered by a revamped electronics platform with 5 times the processing power of its predecessor.

ADVANTAGES OVER PREVIOUS MODELS:

- ACCELERATED PRINT SPEEDS: Up to 4 times faster than earlier models, greatly enhancing productivity.

- IMPROVED MOTION PLANNING: The UltiMaker Cheetah motion planner offers more precise control, reducing print imperfections.

- HIGHER MATERIAL FLOW: New print cores provide increased material flow, supporting faster and more efficient printing.

- ENHANCED PROCESSING POWER: The updated electronics platform delivers 5 times the processing capability of previous versions.

- EXPANDED MATERIAL COMPATIBILITY: Access to a broader range of materials, including advanced composites like Nylon CF Slide.

- SEAMLESS ECOSYSTEM INTEGRATION: Enhanced connectivity with UltiMaker's software ecosystem for a more streamlined user experience.

SUMMARY:

The UltiMaker S8 3D Printer sets a new standard in the industry by combining speed, precision, and versatility. Its advanced features, seamless software integration, and extensive material compatibility make it a valuable asset for professionals seeking to enhance their additive manufacturing processes. Whether for rapid prototyping or production-ready components, the S8 offers a comprehensive solution tailored to meet the evolving needs of modern manufacturing.

-

Consumables

Unlock a wide range of applications with Ultimaker materials or use almost any 2.85mm filament available on the market.

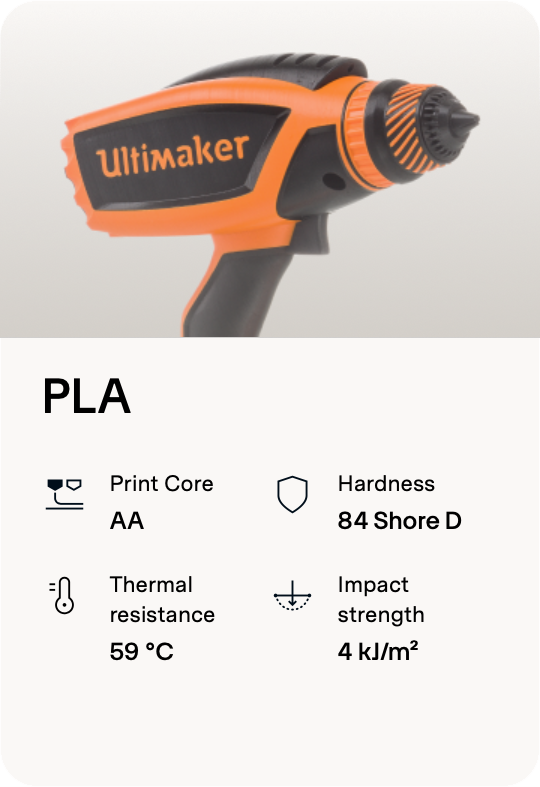

EASY TO PRINT:

Ultimaker PLA (750g)

- PLA - Green - 750g (1608)

- PLA - Black -750g (1609)

- PLA - Silver Metallic - 750g (1612)

- PLA - White - 750g (1613)

- PLA - Transparent - 750g (1614)

- PLA - Orange - 750g (1615)

- PLA - Blue - 750g (1616)

- PLA - Magenta - 750g (1617)

- PLA - Red - 750g (1618)

- PLA - Yellow - 750g (1619)

- PLA - Pearl White - 750g (1620)

Ultimaker Tough PLA (750g)

- Tough PLA - Black - 750g (202300)

- Tough PLA - White - 750g (202301)

- Tough PLA - Red - 750g (202302)

- Tough PLA - Green - 750g (202303)

- Tough PLA - Grey - 750g (202304)

- Tough PLA - Yellow - 750g (202305)

- Tough PLA - Blue - 750g (202306)

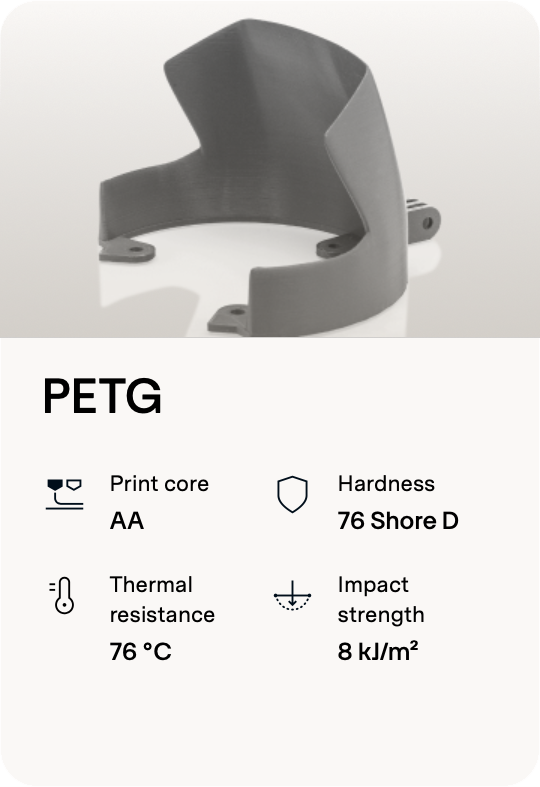

Ultimaker PETG (750g)

- PETG - Black - 750g (227282)

- PETG - White - 750g (227293)

- PETG - Silver - 750g (227326)

- PETG - Grey - 750g (227329)

- PETG - Green - 750g (227330)

- PETG - Transparent - 750g (227332)

- PETG - Blue - 750g (227333)

- PETG - Blue Translucent - 750g (227335)

- PETG - Red - 750g (227336)

- PETG - Red Translucent - 750g (227337)

- PETG - Green Translucent - 750g (227338)

- PETG - Yellow - 750g (227340)

- PETG - Yellow Fluorescent - 750g (227342)

- PETG - Orange - 750g (227343)

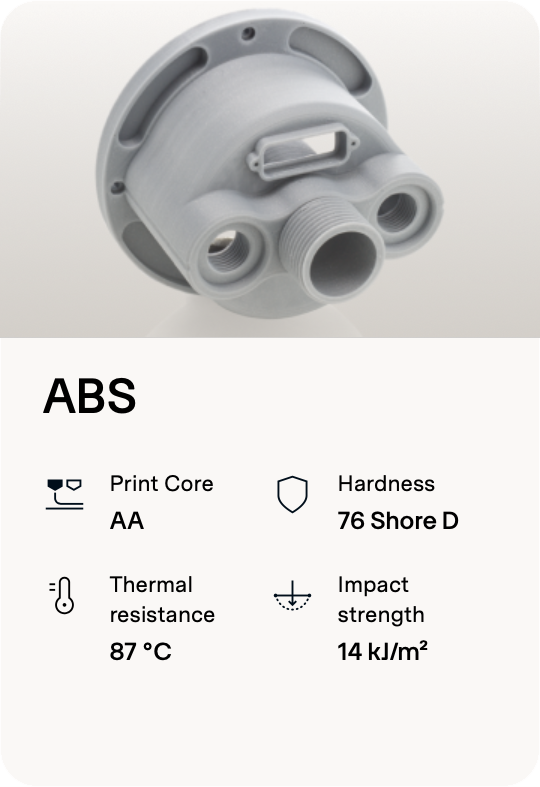

MECHANICAL STRENGTH:

Ultimaker ABS (750g)

- ABS -Black - 750g (1621)

- ABS -White - 750g (1622)

- ABS -Red- 750g (1623)

- ABS -Blue- 750g (1624)

- ABS -Silver- 750g (1625)

- ABS -Pearl Gold - 750g (1626)

- ABS -Green - 750g (1627)

- ABS -Orange - 750g (1628)

- ABS -Yellow - 750g (1629)

- ABS -Grey - 750g (1630)

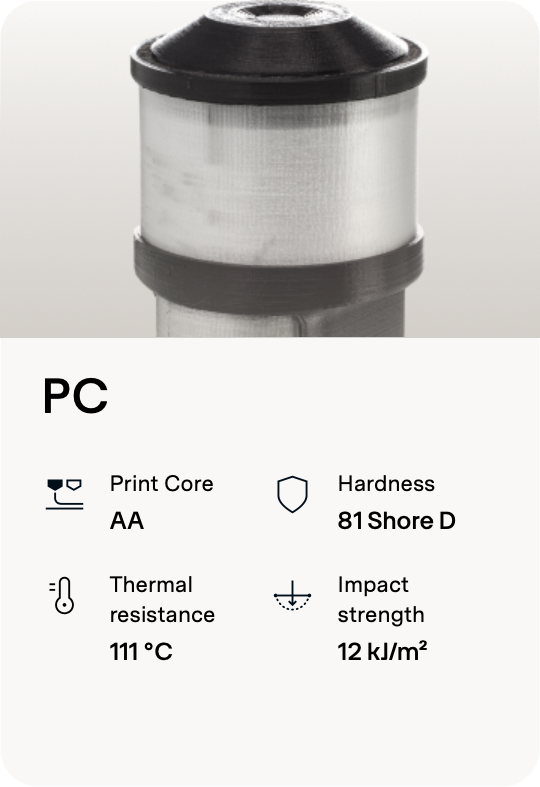

Ultimaker PC (Polycarbonate) (750g)

- Polycarbonate - Transparent - 750g (1640)

- Polycarbonate - Black - 750g (1641)

- Polycarbonate - White - 750g (1642)

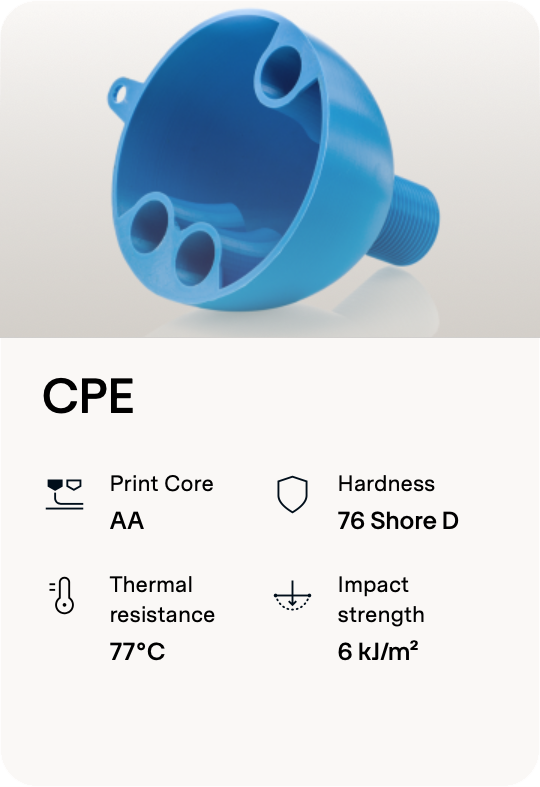

Ultimaker CPE (750g)

- CPE - Black - 750g (1631)

- CPE - White - 750g (1632)

- CPE - Light Grey - 750g (1633)

- CPE - Dark Grey - 750g (1634)

- CPE - Red - 750g (1635)

- CPE - Blue - 750g (1636)

- CPE - Yellow - 750g (1637)

- CPE - Green - 750g (1638)

- CPE - Transparent - 750g (1639)

WEAR RESISTANCE:

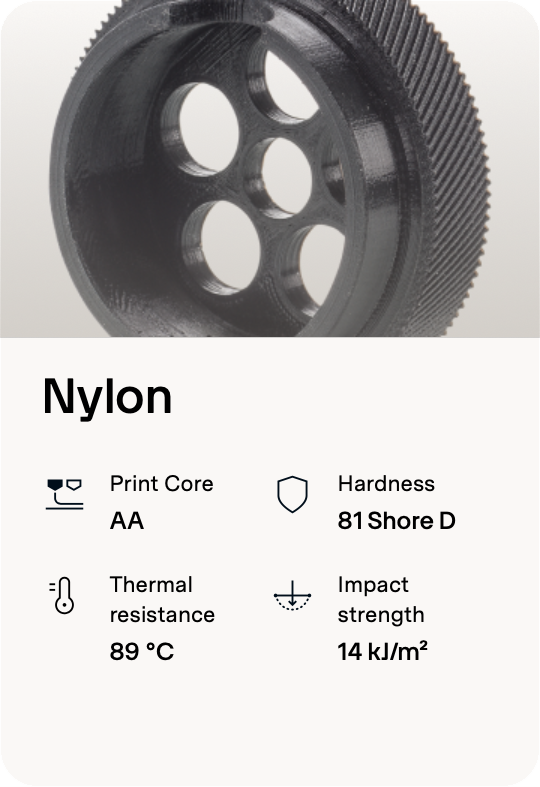

Ultimaker Nylon (750g)

- Nylon - Black - 750g (1646)

- Nylon -Transparent - 750g (1647)

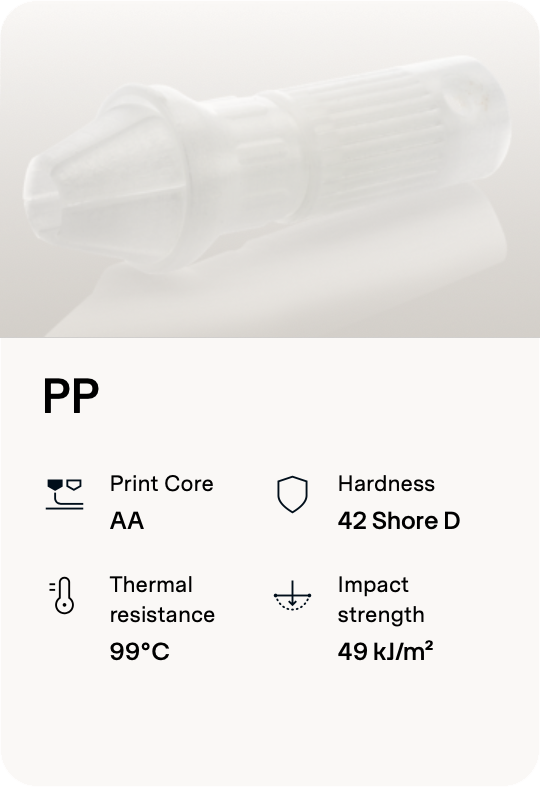

Ultimaker PP (500g)

- Polypropylene – Natural - 500g (1785)

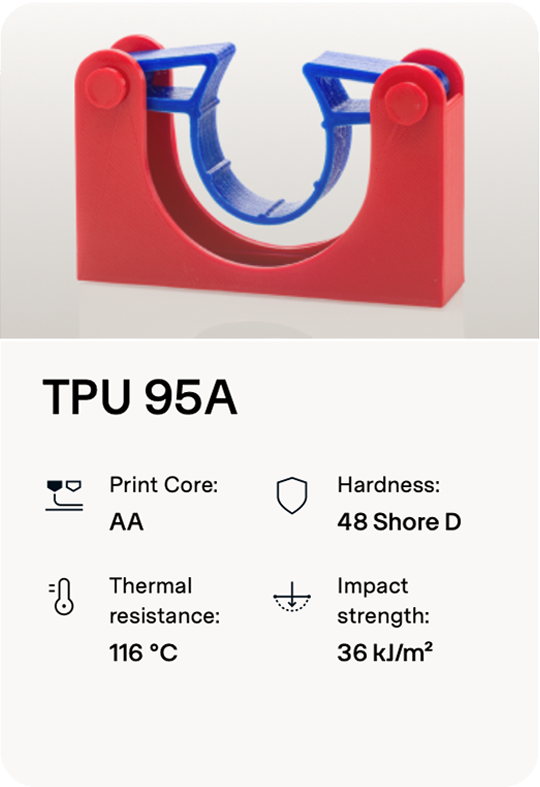

Ultimaker TPU 95A

- Ultimaker TPU 95A Blue Filament 700g (236593)

- Ultimaker TPU 95A Red Filament 700g (236590)

- Ultimaker TPU 95A White Filament 700g (236591)

- Ultimaker TPU 95A Black Filament 700g (236592)

HEAT RESISTANCE:

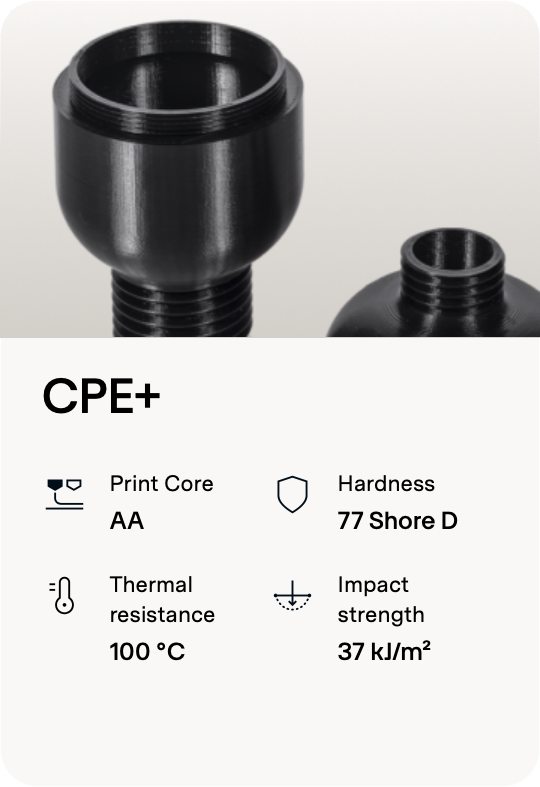

CPE (co-polyester) materials stand out for their exceptional qualities, showcasing chemical resistance, toughness, and impressive dimensional stability. This makes CPE a preferred material for a wide range of applications, including both functional prototypes and mechanical parts. While both CPE and CPE+ share similar performance characteristics, CPE+ offers additional advantages. Notably, it boasts higher temperature resistance and increased impact strength, making it an excellent choice for applications where these specific attributes are crucial. Whether opting for CPE or CPE+, users can rely on these co-polyester materials to deliver durability and reliability in the creation of functional and robust 3D-printed components.

CPE VS CPE+

- CPE offers a diverse selection of colors, providing users with a broad palette to choose from. This includes the sophisticated greyscale option, which adds a professional touch to 3D-printed models.

- CPE exhibits notable strength with higher tensile and flexural strength. On the other hand, CPE+ takes toughness to the next level. Formulated to be up to 10 times tougher than standard CPE, CPE+ is engineered to provide enhanced durability and resilience.

- CPE+ features a temperature resistance of up to 100ºC when compared to CPE, which is only resistant up to 70ºC

Ultimaker CPE+

- Ultimaker CPE+ Transparent Filament 700g (1643)

- Ultimaker CPE+ Black Filament 700g (1644)

- Ultimaker CPE+ White Filament 700g (1645)

-

Optional Material Station

ULTIMAKER S8 PRO BUNDLE:

The Pro Bundle optimises your 3D printing process through its automatic material handling, effective air filtering, and precise filament humidity control. Collectively, these capabilities open the door to continuous 24/7 productivity, catering to the needs of demanding applications and accommodating a broader spectrum of materials for your creative endeavors. This option includes the S8 3D Printer and MATERIAL STATION.

The Ultimaker S5/S7/S8 Material Station marks an important contribution to a ‘no-hassle’ office solution. As part of the Ultimaker S8 Pro Bundle, it features easy front loading for up to six spools of filament, end-of-filament detection, NFC recognition with compatible materials, and automatic material switching.

The Ultimaker Material Station stands as an advanced humidity-controlled chamber designed to accommodate six material spools, allowing flexible loading of up to 4.5kg of material in any order. Boasting cutting-edge features, each bay within the station incorporates automatic material switching, composite-ready feeder wheels, and filament flow sensors.

KEY FEATURES:

- FAST & EASY LOADING: Front-facing bay for up to six materials reduces loading time to a few seconds

- UNINTERRUPTED PRINTING: Sensors detect when one material spool ends and automatically loads the next

- HUMIDITY CONTROL: Intelligent atmospheric management keeps relative humidity below 40%

- EASY SET-UP & MONITORING: NFC material auto- recognition and seamless integration with Ultimaker software

- COMPOSITE MATERIALS COMPATIBLE: Print parts with high strength and unique properties

- LIMITLESS CONFIGURATIONS: Keep your most-used materials ready to print when you need – Ultimaker and third-party filaments

-

Optional PVA Removal Station

Experience quicker and easier post-processing when using PVA support material for complex parts or stunning visual prototypes, with the Ultimaker PVA Removal Station. Part of our start-to-finish 3D printing platform, it ensures quicker design iterations with minimal operator time and no mess.

A rinsing basket keeps your print in place and completely submerged while dissolving, then lifts up for mess-free draining and print removal.

MAIN FEATURES:

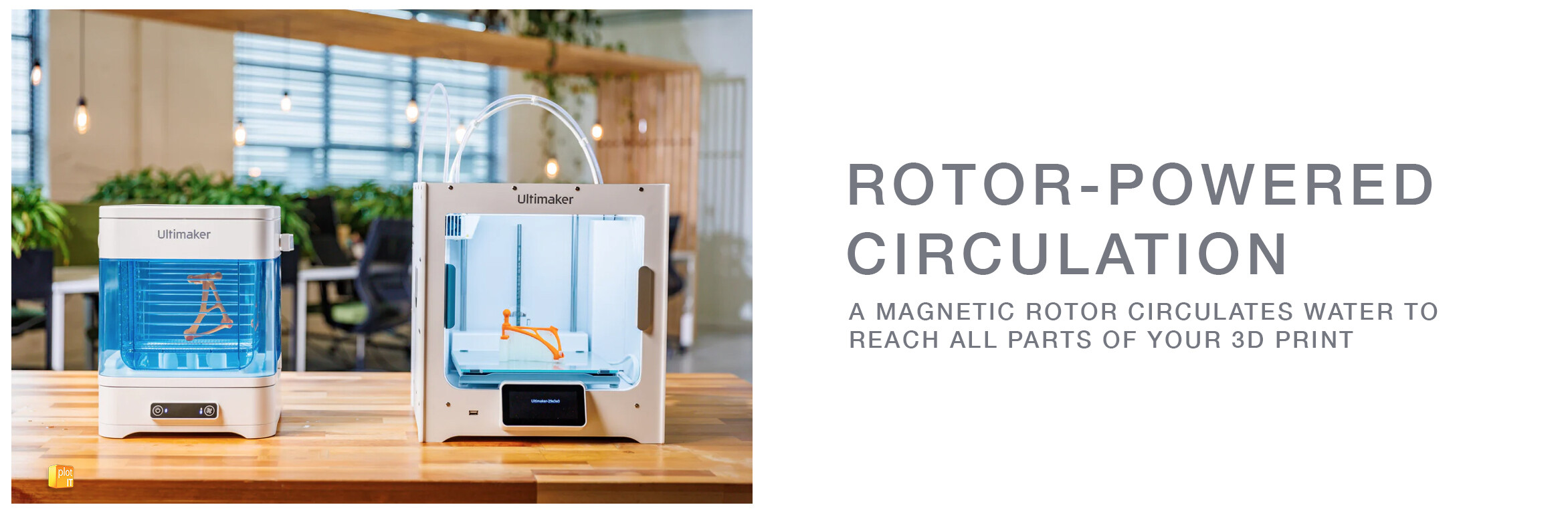

- ROTOR-POWERED CIRCULATION: A magnetic rotor circulates water to reach all parts of your 3D print

- ADJUSTABLE ROTOR SPEED: Adjust for faster dissolving or to protect fragile parts

- KEEPS PRINTS SECURED: A rinsing basket keeps prints in place and submerged

- EASY TO FOLLOW PROGRESS: A transparent, illuminated container makes it easy to know exactly when your part is ready

- LOW MAINTENANCE: Ergonomically designed for easy cleaning

- NO CHEMICALS NEEDED: Just fill with regular tap water, which can be safely disposed of when finished

- CLEAN & NO MESS: Ergonomic design features help keep your workspace clean and tidy

A transparent, illuminated container lets you easily follow the PVA removal process and see when your part is ready. Plus, a saturation indicator shows when to refresh the water.

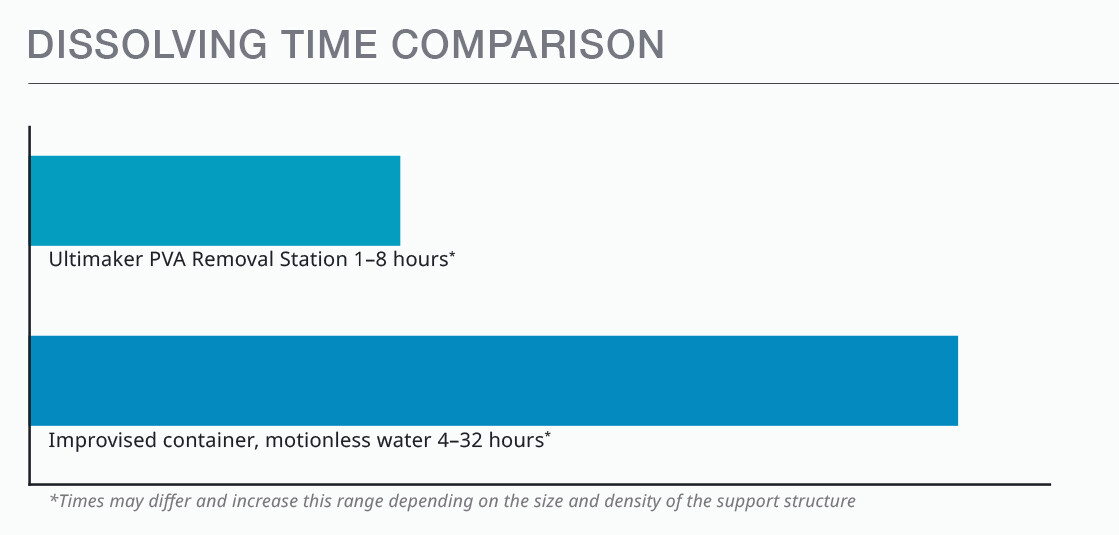

The Ultimaker PVA Removal Station features a high-speed dissolving process driven by a magnetic rotor. Compared with motionless water in an improvised container, it removes PVA up to four times faster – even from hard-to-reach cavities in complex designs. So you have parts ready as soon as possible.

The PVA Removal Station requires only a few minutes of operator time per print, and almost zero maintenance. Just press the start button. Leave it to spin. And collect your print when it’s ready.

Choose 100 or 225 RPM circulation depending on the fragility of your part. Every two minutes, the rotor changes direction to push water evenly against the model. A rinsing basket keeps your print in place and completely submerged while dissolving, then lifts up for mess-free draining and print removal.

-

Tech specs & Comparison Chart

TECH SPECS:

SPECIFICATION DETAILS Build Volume 330 x 240 x 300 mm (13 x 9.4 x 11.8 inches) Assembled Dimensions W 495 x D 585 x H 800 mm (W 19.5 x D 23 x H 31.5 inches) Print Technology Fused Deposition Modeling (FDM) Compatible Filament Diameter 2.85 mm Weight 29.1 kg (64.2 lbs) Maximum Power Output 500 W Dimensional Accuracy ± 0.15 mm ± 0.15% feature nominal length* Extrusion Flow Up to 35 mm3/s XY Speed, Acceleration, Jerk Up to 500 mm/s, up to 50,000 mm/s², up to 100,000,000 mm/s³ Layer Resolution 0.25 mm nozzle: 150 - 60 micron

0.4 mm nozzle: 200 - 20 micron

0.6 mm nozzle: 300 - 20 micron

0.8 mm nozzle: 600 - 20 micronXYZ Resolution 6.9, 6.9, 2.5 micron Feeder Type Dual-geared feeder, reinforced for composite materials Display 4.7-inch (11.9 cm) color touchscreen Print Core Replacement Swappable print cores Print Head Dual extrusion print head with auto-nozzle lifting system, swappable print cores, and flood detection. Nozzle Diameters 0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm Filter Technology Replaceable EPA filter Air Extraction Rate 1 - 50 m³/h (35 m³/h nominal rate for most materials at 23 °C) Nozzle Temperature Up to 340 °C (644 °F) Nozzle Heat-up Time < 2 minutes Operating Sound < 50 dBA Build Plate Leveling Advanced active leveling with more accurate inductive sensors Build Plate PEI-coated flexible steel build plate Build Plate Heat-up Time < 5 minutes (from 20 to 60 °C) Operating Ambient Temperature 15 - 32 °C (59 - 90 °F) Non-operating Temperature 0 - 32 °C (32 - 90 °F) Supplied Free Software UltiMaker Cura – print preparation software

UltiMaker Digital Factory – All-in-one cloud-based print, printer, and user management softwareSupported OS macOS, Windows, and Linux Plugin Integration SolidWorks, Siemens NX, Autodesk Inventor Supported File Types UltiMaker Cura: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG

Printable formats: G, GCODE, GCODE.gz, UFPFile Transfer Wi-Fi 2.4 & 5 GHz: IEEE 802.11a/b/g/n/ac

LAN: Gigabit Ethernet

USB: 2.0Certification CE, FCC, VPAT, RoHS, REACH, CB, BIS, KC, PSE, RCM, SRRC, MIC, NCC, Safe unattended professional use COMPARISON TABLE: ULTIMAKER S8 VS S7

Feature UltiMaker S8 UltiMaker S7 Print Speed Up to 500 mm/s Up to 250 mm/s Acceleration Up to 50,000 mm/s² Up to 20,000 mm/s² Motion Planner UltiMaker Cheetah Motion Planner Standard Motion Control Processing Power 5x that of previous models 2x that of previous models Feeder System Hardened feeder module Standard feeder module Print Core Type AA+ and CC+ high-flow print cores AA and CC standard-flow cores Material Compatibility Over 300 materials, including Nylon CF Slide (180°C stability) Wide material compatibility Max Print Temperature Up to 280°C Up to 280°C Air Quality Management Integrated EPA filter (removes up to 95% of ultrafine particles) Integrated Air Manager Software UltiMaker Digital Factory, Cura Cloud UltiMaker Digital Factory, Cura Connectivity Wi-Fi, Ethernet, USB Wi-Fi, Ethernet, USB -

Training

Ultimaker 3D Printer training is available to cover all aspects of your new 3D printer including advanced level with the “Design for Additive” half day extension course, training is for up to 3 people on site with delivery of your new Ultimaker & we also run regular training courses at our Stoke Offices and for larger groups at our Worcester HQ , Bristol or Derby facilities.

INST002 INSTALLATION & TRAINING PACKAGES *

* INSTALLATION (IN CONJUNCTION WITH CUSTOMER):

Unboxing of printer and material station – connect units together Setup of Printer onto the network Setup of the printer into Cura and the Digital factory

* TRAINING (SOFTWARE & HARDWARE):

- Using Cura Slicing software to prepare parts for printing

- Cura setting

- Preview of time to print and cost to print

- Submitting prints

- Monitoring prints

- Loading and unloading of material on the printer

- Changing Cores

- Maintenance of the printer

- Tips and tricks

DfAM002 DESIGN FOR ADDITIVE (½ DAY) * & **

** DESIGN FOR ADDITIVE MANUFACTURING COURSE:

- Design rules for manufacturing

- Designing for FDM

- Exporting from CAD

- Orientation considerations

- Walls and Ribs

- Slice height and toolpaths

- Self-supporting designs

- Sectioning parts

- Assemblies / Moving parts

- Threads / Inserts

- Infills Tolerances

- Design samples discussed

- Various exercises to be completed though out the session

Download a Brochure

-

UltiMaker S8 3D Printer (64-237331) - DATA SHEET

Download