- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Bricsys BricsCAD® Software

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

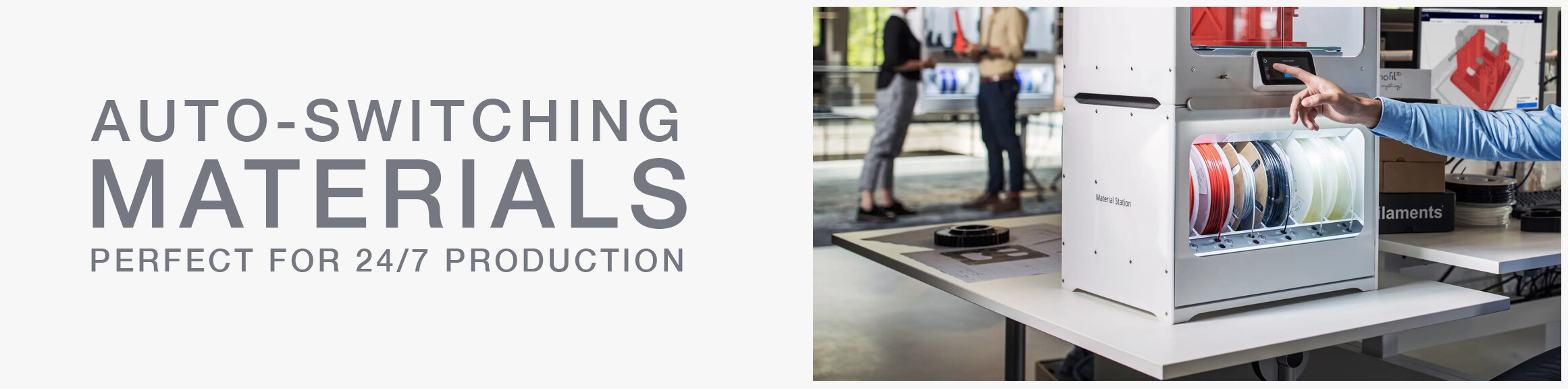

Ultimaker S5/S7/S8 Material Station (218053)

-

Description

Seamlessly integarating with the Ultimaker S5/S7 and S8, the Material Station redefines material handling – to unlock truly 24/7 production. Load up to six material spools inside the humidity- controlled chamber and smart features take care of the rest: Composite-ready feeder wheels, filament flow sensors, and automatic switching when a material runs out. Now you can achieve increased productivity and higher-quality production.

The Ultimaker S5/S7/S8 Material Station marks an important contribution to a ‘no-hassle’ office solution. As part of the Ultimaker S5 Pro Bundle, it features easy front loading for up to six spools of filament, end-of-filament detection, NFC recognition with compatible materials, and automatic material switching.

The Ultimaker S5/S7/S8 Material Station Material Station stands as an advanced humidity-controlled chamber designed to accommodate six material spools, allowing flexible loading of up to 4.5kg of material in any order. Boasting cutting-edge features, each bay within the station incorporates automatic material switching, composite-ready feeder wheels, and filament flow sensors.

KEY FEATURES:

- FAST & EASY LOADING: Front-facing bay for up to six materials reduces loading time to a few seconds

- UNINTERRUPTED PRINTING: Sensors detect when one material spool ends and automatically loads the next

- HUMIDITY CONTROL: Intelligent atmospheric management keeps relative humidity below 40%

- EASY SET-UP & MONITORING: NFC material auto- recognition and seamless integration with Ultimaker software

- COMPOSITE MATERIALS COMPATIBLE: Print parts with high strength and unique properties

- LIMITLESS CONFIGURATIONS: Keep your most-used materials ready to print when you need – Ultimaker and third-party filaments

-

Properties

Filament diameter: 2.85 mm

Material spool dimensions: Width: 50 - 70 mm (2 - 2.7 in)

Diameter: 197 - 203 mm (7.8 – 8 in)

Core diameter: > 98 mm (3.8 in)

Material capacity: 6 spools

Material recognition: Auto-recognition enabled with NFC scanner Feeder type: Dual-geared, abrasion-resistant

Data connection: UMB connection (included)

Compatible materials: Optimised for Ultimaker PLA, Tough PLA, ABS, Nylon, CPE, CPE+, PC, PP, TPU 95A, PVA, Breakaway (Also supports third-party materials)

-

Which Material Station Set Up?

WHICH MATERIAL STATION SET-UP?

The Ultimaker S5/S7/S8 Material Station marks an important contribution to a ‘no-hassle’ office solution. As part of the Ultimaker S5 Pro Bundle, it features easy front loading for up to six spools of filament, end-of-filament detection, NFC recognition with compatible materials, and automatic material switching. But how best to configure your Material Station for your use case? Read on for a few tips.

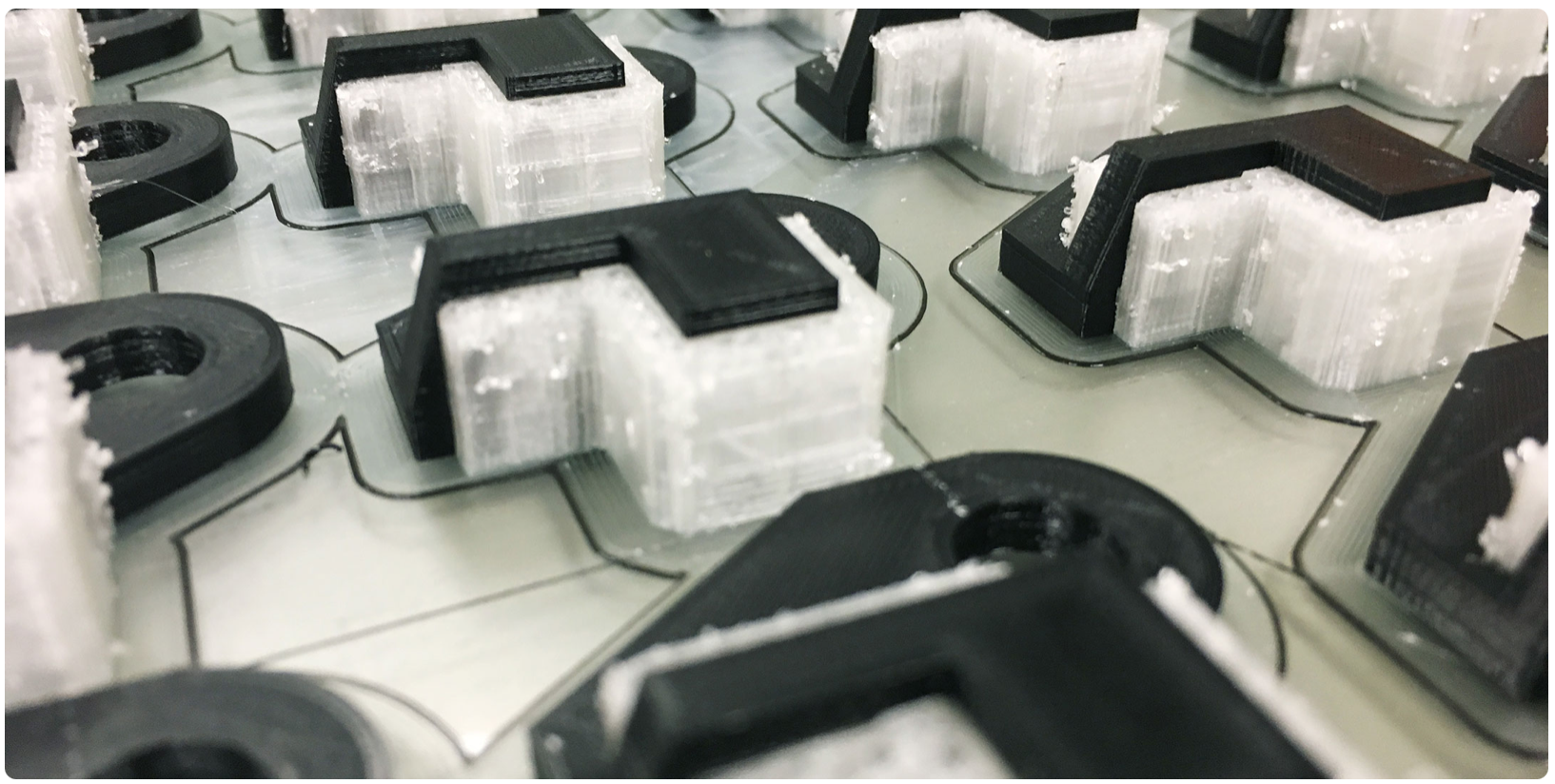

STAY CONSISTENT

Model-making, prototyping, production runs often require only one print color. For these cases – and for large, time-consuming prints – the Material Station is best loaded with six spools of the same color of filament, allowing you to greatly limit time spent replacing print material. Just start printing and get on with your day.

STAY STABLE

Complex prints often require support material to prevent overhangs from collapsing. By loading the Material Station with three spools of regular material and three spools of support materials like Breakaway or PVA – or a four-two division, depending on the amount of each type of material needed – you will ensure that your prints come out stable and ready for action. A fully enclosed chamber keeps relative humidity below 40%, meaning PVA, which degrades when not properly stored, can be kept for much longer periods of time, eliminating the potential for wastage.

Other materials, such as glass fiber-reinforced nylon, will also degrade if not kept at proper humidity. The Material Station provides a suitable environment for these materials and many others available within the Ultimaker Marketplace.

STAY ORGANISED

In a fast-paced environment such as a manufacturing line, the use of multiple tools, jigs, and fixtures is all but required. To keep things moving – and to maintain an appropriate level of safety – colour-coding is an excellent option. With the Material Station, this is easily done.

Going further, battery-style indicators in Ultimaker Cloud and Ultimaker Connect show material amount status, so you know which materials to load next. These indicators are also reflected on the interface of the Ultimaker S5/S7/S8.

Download a Brochure

-

Ultimaker S5/S7/S8 Material Station (218053) - ULTIMAKER S5 MATERIAL STATION

Download