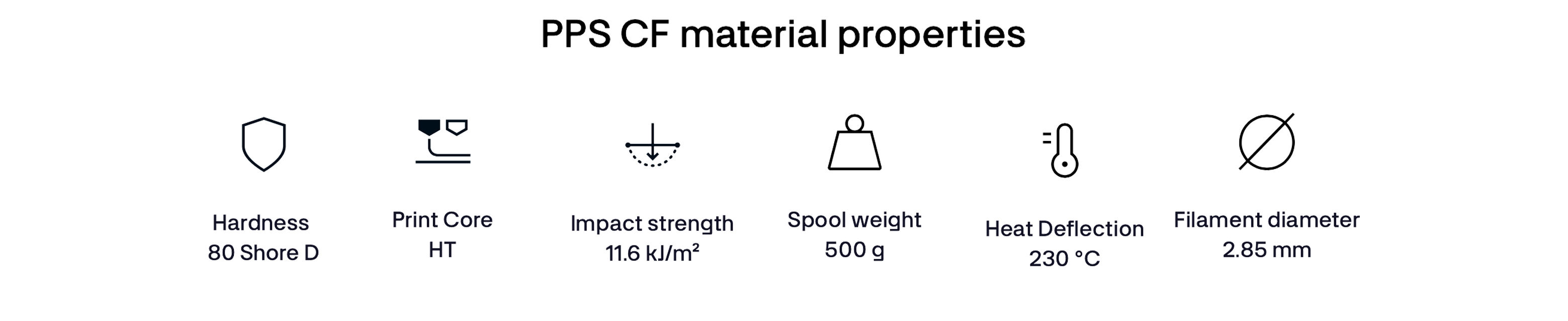

UltiMaker PPS CF 500g Filament (235802): Introducing UltiMaker PPS-CF, an advanced high-temperature composite engineered for Factor 4, designed to replace intricate steel components. With a heat deflection temperature exceeding 230°C, it offers exceptional chemical resistance and flame retardancy (UL94 V0), rendering it a versatile and reliable option for the most challenging of applications.

Engineered to endure the demands of real-world applications, PPS CF (polyphenylene sulfide reinforced with 10% carbon fiber) offers exceptional chemical resistance, heat resistance, and dimensional stability. With these outstanding qualities, you can trust that your industrial prototypes or functional end-use parts will deliver lasting performance, ensuring your confidence in every application.

UltiMaker PPS CF is meticulously developed, ensuring precision and attention to detail. With minimal filament diameter variance across the entire spool, it guarantees consistent flow and exceptional print quality. Paired with the cutting-edge technology of UltiMaker Factor 4 and Cura's streamlined slicing workflow, it provides hassle-free printing with a dimensional accuracy of ± 0.2 mm or ± 0.2% and a smooth surface finish. This makes it the perfect choice for producing small batches of auxiliary components and spare parts that require reliable and repeatable results.

UltiMaker PPS CF offers a high-performance alternative to steel or aluminum, particularly for less-demanding parts. Its exceptional properties make it a viable substitute for PEEK, providing a more cost-effective, reliable, and easier 3D printing experience.

Crafted with meticulous attention to detail, UltiMaker PPS CF guarantees consistent flow and exceptional print quality. Enjoy a hassle-free printing experience with outstanding dimensional accuracy, ensuring your designs come to life with unparalleled precision and reliability.

UltiMaker PPS CF opens up a new category of 3D printing applications, perfectly compatible with UltiMaker Factor 4 and print core HT. This semi-crystalline thermoplastic offers a remarkable heat deflection temperature of over 230°C post-printing. Highly resistant to chemicals, it remains undamaged by solvents below 200°C. Additionally, it meets the UL94 V0 standard for flame retardancy, ensuring safety and reliability in various applications.

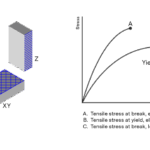

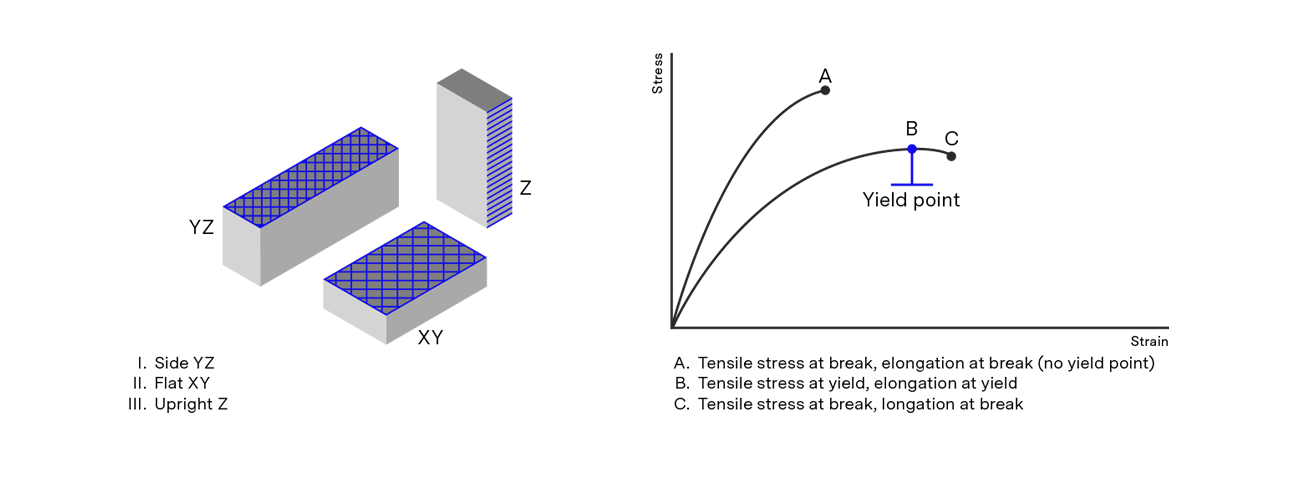

PRINT ORIENTATION:

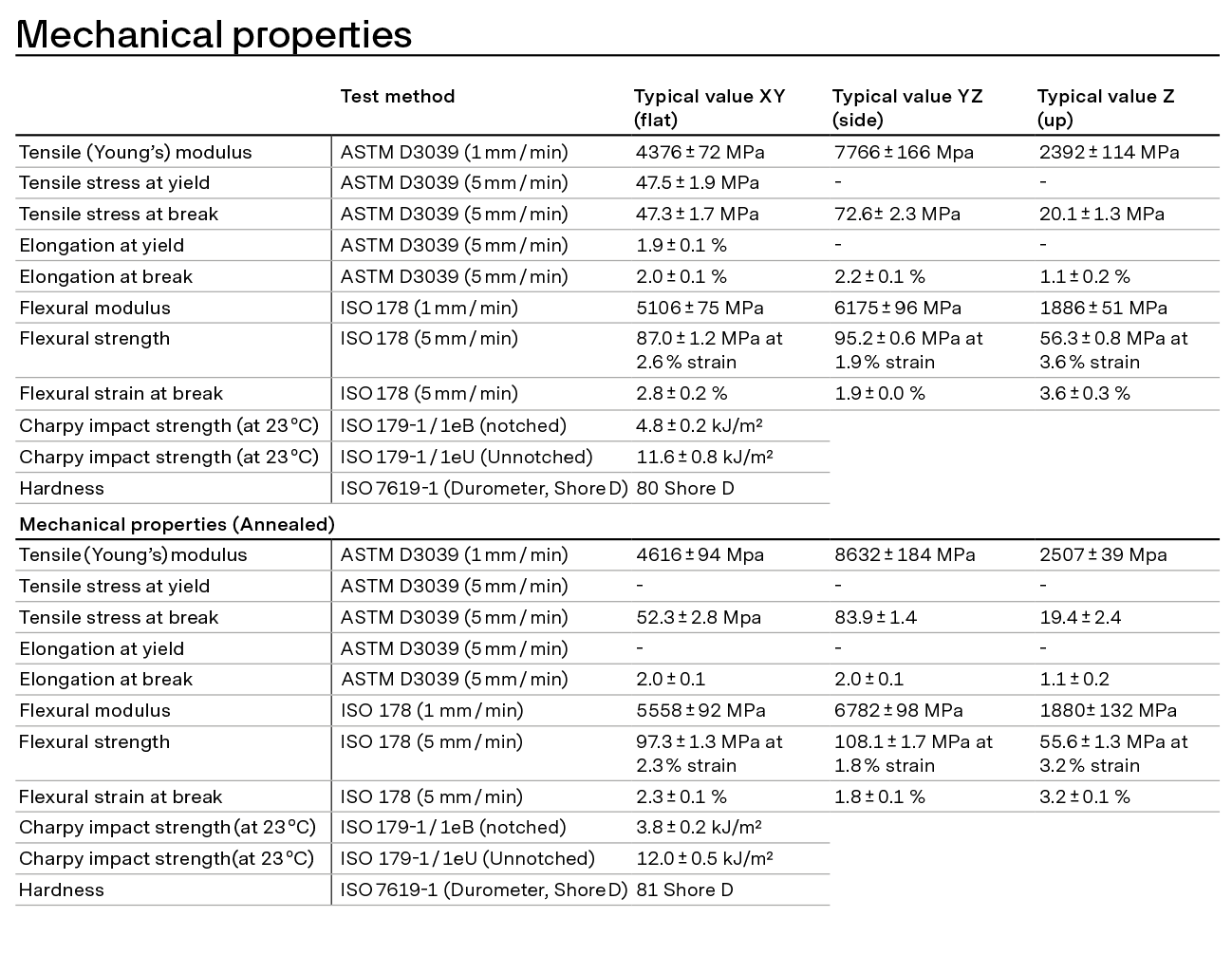

Given the layered nature of the FDM process, the mechanical properties of a part vary based on its orientation. Differences are notable between in-plane components, such as walls (conforming to the part's contours) and infill (formed by 45° lines). This contrast is evident in XY data (printed flat on the build plate, primarily infill) and YZ data (printed on its side, mainly walls). Furthermore, the upright orientation (Z direction) provides insight into the material's interlayer adhesion strength, typically exhibiting the lowest strength in FDM. All samples are printed with 100% infill, with blue lines in the illustration indicating the typical directionality of infill and walls in a printed part.

KEY FEATURES:

- Replace metal and PEEK parts with a cost effective and easy to manufacture solution.

- PPS CF prints reliably in great precision on the UltiMaker Factor 4 yielding flame retardant, temperature resistant (>230°C) and chemical resistant (insoluble in all solvents below 200°C) parts.

- Great strength and stiffness with next level durability

APPLICATIONS:

- Functional prototyping

- Tooling

- Manufacturing aids in various industries such as automotive, railway, aerospace.