- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Bricsys BricsCAD® Software

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

Summa S Class 3 S160 T-Series 63” 1600mm Cutter S3T160

- Description

- Other related models

- Model Comparison

- Range Tech Specs

- Drag vs Tangential

- Cutting Technologies

-

Description

Summa is proud to announce a brand-new vinyl cutter product line. The Summa S Class 3 is a state-of-the-art device designed for professional users who demand top performance in their cutting applications and want to explore new opportunities.

Summa S Class 3 S160 T-Series 63” 1600mm Cutter S3T160: The versatile T Series gives you Summa S Class power and precision with a state-of-the-art True Tangential cutting head. It employs Summa's most powerful servomotors yet & MicroSprocket drive to let you cut with amazing speed confidence and precision. Coupled with an astonishing array of innovations and built-in capabilities Summa S Class does more than any other cutter in its class.

Summa S Class 3 S160 T-Series 63” 1600mm Cutter S3T160: The versatile T Series gives you Summa S Class power and precision with a state-of-the-art True Tangential cutting head. It employs Summa's most powerful servomotors yet & MicroSprocket drive to let you cut with amazing speed confidence and precision. Coupled with an astonishing array of innovations and built-in capabilities Summa S Class does more than any other cutter in its class.

The S3 160 is a must-have for professionals seeking peak versatility and productivity. With its expansive capability to handle media up to 158cm (extendable to 165cm in oversized mode), it's tailor-made for large-scale projects. Featuring advanced cutting technology and your choice of a drag or tangential knife, it delivers unrivaled control and pressure, ensuring precision and efficiency with every cut.

Experience the pinnacle of automation with the Summa S3 160. Simply position a printer in front of the roll cutter, and enjoy seamless transitions from printing to cutting without any manual intervention. Plus, with the roll-up unit option, you can neatly roll up processed materials instead of having them accumulate in the basket.

In need of even more cutting prowess? Look no further than the Twin X functionality, offering the ultimate solution by seamlessly integrating the Summa S3 160 with the F1612 flatbed cutter. This dynamic pairing optimizes workflow efficiency, propelling your business to unprecedented heights of success.

KEY FEATURES:

- 2.8" Connectivity options

- Media width up to 168 cm

- Summa GoSign software

- Tangential knife technology

- Legendary tracking performance

- Indicator light

- Advanced throughcut functionality

- Camera or sensor recognition of registration marks

- Barcode functionality for automation

- Twin X functionality

- Roll-up system

G PERFORMANCE MODE (OPTIONAL):

Engaging this mode on the S Class 3 roll cutters can significantly enhance production speed by up to 40%, contingent upon the nature of the cutting task. This acceleration is particularly pronounced during swift registration mark detection and when processing wider substrates. Consequently, default jobs are executed at a notably accelerated pace. G-performance is tailored for users seeking to maximize yield, facilitating the processing of jobs at higher than average speeds.

EASE OF USE:

Experience enhanced user-friendliness with a status bar illuminated in blue, green, and red, providing intuitive feedback at a glance. Easily pinpoint adjustable components with their distinctive blue coloring. Complementing this feature is a thoughtfully positioned tool tray at the rear, ensuring efficient and seamless operation.

LARGER MEDIA ROLL:

The media roll capacity of the cutter has been enhanced to accommodate a diameter of 20cm, with support for a minimum roll weight of 45kg. This upgrade proves immensely advantageous for print and cut applications, particularly those involving laminated vinyl, ensuring smoother and more efficient operations.

SERVO-POWERED ROLL-UP SYSTEM (S3 140 & S3 160):

Upon completion of a job, the system will meticulously roll up the artwork, preparing the machine seamlessly for the next task. The integrated panelling feature intelligently divides lengthy runs into shorter, consecutive tasks, enabling the cutting of entire rolls without requiring constant supervision and delivering neatly rolled-up output for added convenience.

APPLICATIONS:

LARGE SIGNS:

The Summa S Class 3 opens the door to commanding attention with your signage endeavors. Whether you're crafting dynamic floor graphics, impactful wall designs, attention-grabbing window stickers, or precise lettering, this machine executes each task with finesse and precision.

Taking your message on the move? Summa roll cutter ensures your vehicle graphics demand attention wherever they roam.

Looking to maintain privacy? The S Class 3 seamlessly transforms your windows into promotional showcases while preserving confidentiality from within. And for indoor attention-grabbers like totems and interior advertising, the S Class 3 handles them with effortless proficiency.

SMALL TEXT & INTRICATE DESIGNS: PRECISION AT ITS BEST:

The Summa S Class 3 stands as the ultimate solution for mastering intricate designs and small letters with unparalleled precision, thanks to Summa's revolutionary Tangential cutting technology. Unlike conventional drag knives, this innovative system elevates and repositions the blade in corners, resulting in impeccably sharp and precise cuts.

But its superiority doesn't end there – equipped with Smart Object Sorting, the S Class 3 intelligently selects the optimal starting point for cutting, while Smart Panelling ensures efficient cutting of all objects within a designated range.

From flawlessly cut keychains and magnets to precise small signage like nameplates, directional signs, and room numbers, this machine excels across a spectrum of applications. Labels and tags, essential for both product branding and organizational purposes, achieve perfection with ease. And for enthusiasts of custom apparel, the S Class 3 delivers impeccable results, whether it's personalized T-shirts, hats, socks, and more.

EVERY TYPE OF STICKER IMAGINABLE:

Elevate your sticker game with the S Class 3! Revolutionising your print and cut workflows like never before, this machine introduces the groundbreaking FlexCut feature.

How does FlexCut transform your workflow? One length is fully cut through the material, while the other is scored halfway, creating a flawless tear-off line. This unique process ensures your material maintains rigidity during transport through the Summa cutter yet remains effortlessly removable from your designs afterward.

The creative possibilities are endless! Whether you're crafting standard vinyl stickers, kiss-cut stickers, die-cut stickers, clear stickers, bumper stickers, holographic stickers, transfer stickers, or even window clings and wall/floor stickers, the S Class 3 handles each task with unparalleled precision and ease.

THICK, THIN & TOUGH MATERIAL:

The versatility of the S Class 3 extends beyond standard laminated vinyl. With its tangential cutting head, this machine can effortlessly handle an array of materials with non-standard thickness, unlocking a realm of cutting possibilities.

Thin materials encompass substances thinner than traditional sticker vinyl, such as car wraps, offering flexibility and precision in cutting. On the other end of the spectrum, thick and resilient materials, often overlapping with the aforementioned category, can reach up to 1.2mm in thickness, including laminated vinyl and folding carton. This breadth of compatibility expands the horizons of what you can achieve with the S Class 3, ensuring unparalleled adaptability across various projects and materials.

CREASING (TC MODELS ONLY):

Exclusive to Summa cutting plotters is the unique ability not only to cut but also to crease. With the innovative Performance Head, the S Class 3 can seamlessly execute both functions within the same job, eliminating the need for tool changes or machine pauses.

The creasing capability lends itself perfectly to short-run applications, making it ideal for crafting bespoke gadgets for events or corporate entities in folding carton.

The versatility of folding carton knows no bounds when paired with the S Class 3. Imagine producing high-quality restaurant menus or personalized greeting cards for special occasions. Short-run leaflets and folders are effortlessly achievable with the S Class 3's precision. Furthermore, the machine enables the creation of custom-designed little boxes, perfect for holding small gifts or business cards.

WHAT'S INCLUDED:

- 2 standard knife blades & standard nose piece

- 1 thick material knife & thick material nose piece

- Blade holder for standard

- Thick material & double-tip knife (requires matching nose piece)

- Ballpoint pen with pen holder

- Power cord

- Serial interface cable (PC)

- USB Cable (PC/Mac)

- Quick start guide

- User's manual & drivers on CD-ROM

-

Other related models

D SERIES:

TC SERIES:

T SERIES:

-

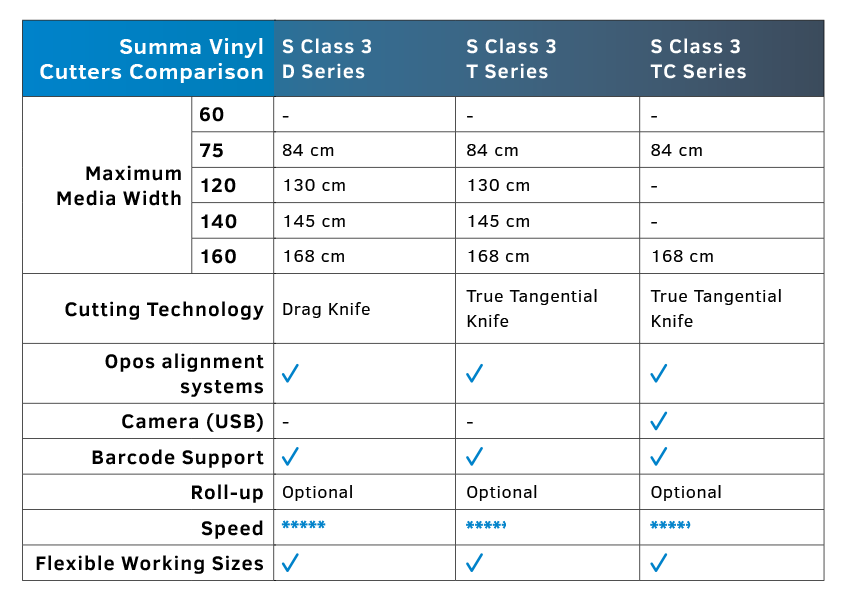

Model Comparison

-

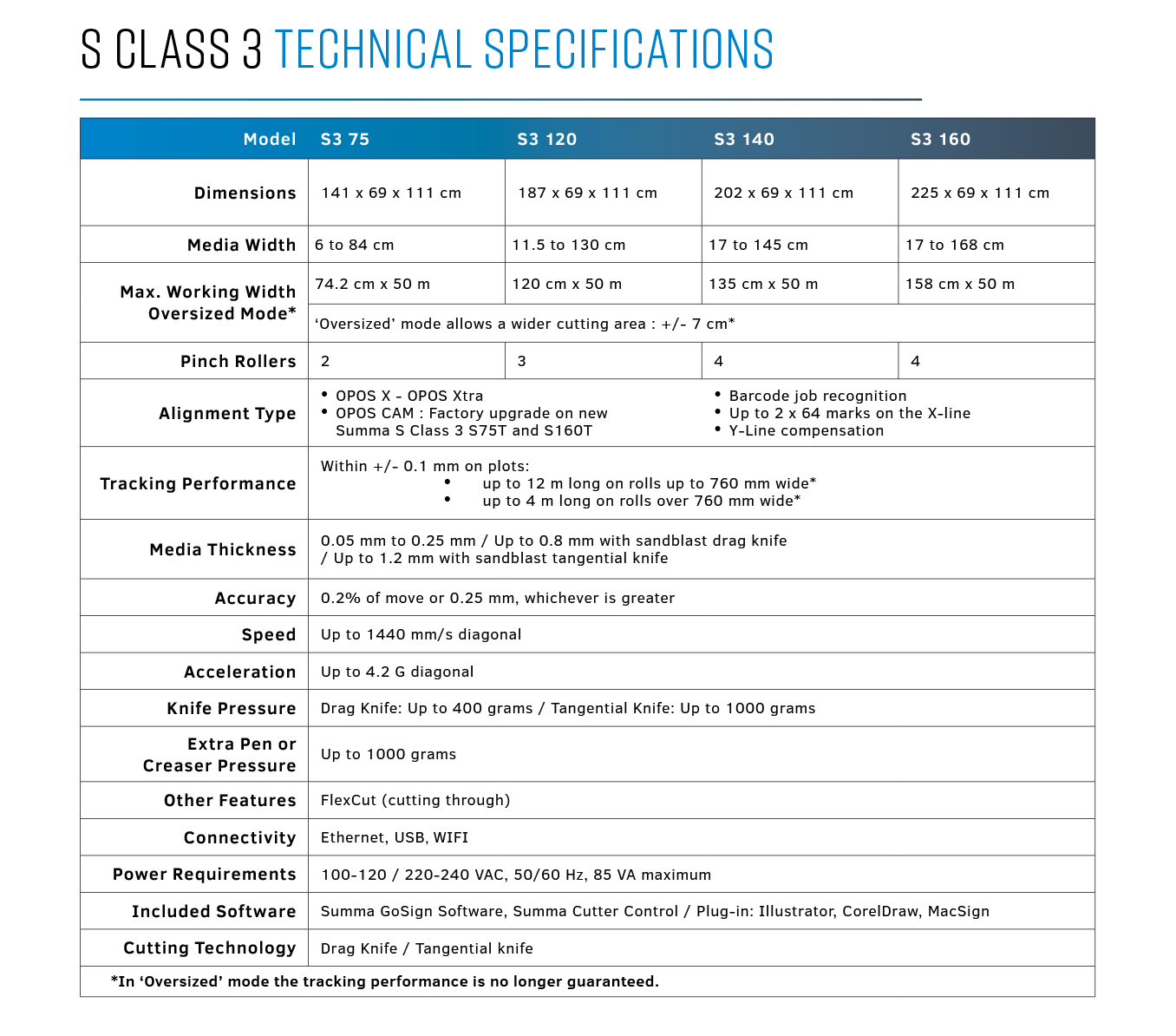

Range Tech Specs

-

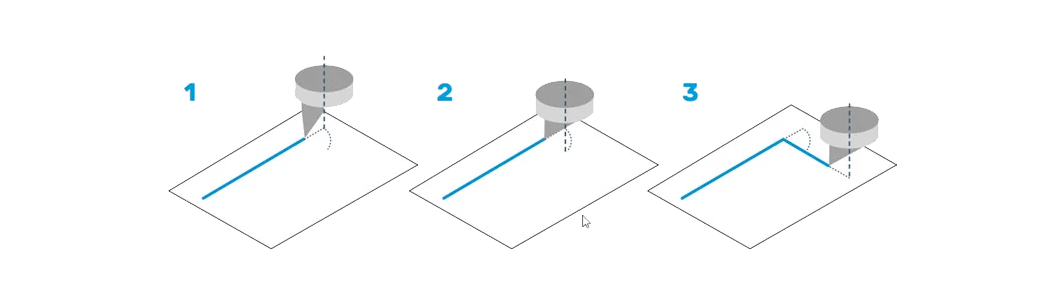

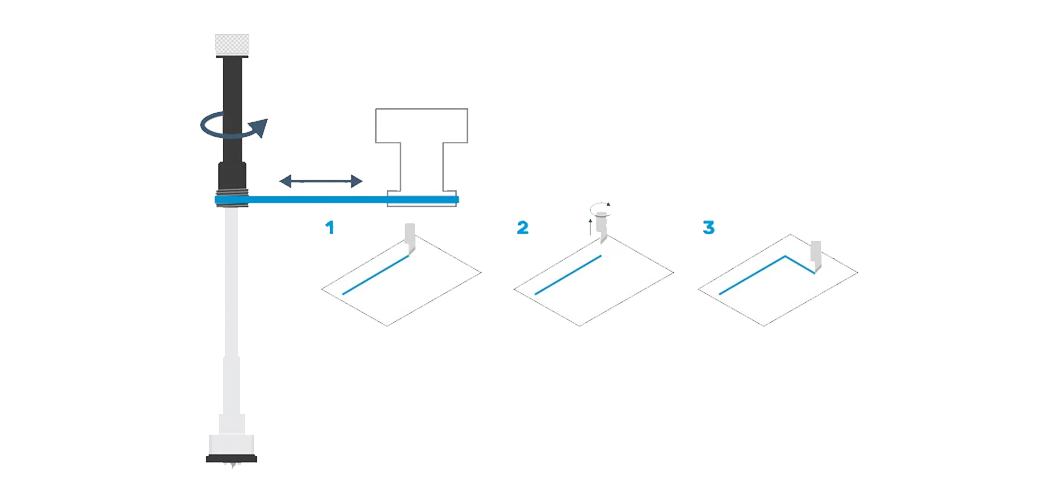

Drag vs Tangential

DRAG KNIFE:

HOW DOES DRAG KNIFE TECHNOLOGY WORK?:

Comparing the drag knife or swivel knife technology to a familiar concept, like a tractor plough, can help illustrate its function. Both tools share common principles:

Firstly, they are both "dragged" through their respective substrates. Just as a plough moves through earth or dirt, the drag knife moves through vinyl or foil.

Secondly, both tools are controlled by external factors. In the case of the plough, it's the tractor that pulls and guides it in the correct direction. Similarly, for the drag knife, the cutting head movement and the movement of the media work together to orientate the knife in the right direction. This combination of movements ensures that the knife faces the correct angle for precise cutting, much like the plough's orientation is adjusted by the tractor's movement.

The drag knife needs to make certain movements in each corner without the ability to lift from the media to make a “sharp” corner. At least that is the theory behind it. Since all these extra movements are done at a minuscule level, it is practically impossible to see this with the naked eye. In its own way, a drag knife might just do the trick, depending on the substrate and the kind of job you want to cut.

HOW DOES DRAG KNIFE RESPOND TO MEDIA?:

The drag knife excels in cutting designs for billboards, light boxes, and window graphics due to its precision and versatility. However, as the thickness of the media increases, corner distortions or deviations may become more noticeable. This can result in slightly rounded corners or the media being pushed up, particularly with softer or more rigid materials.

It's true that the amount of pressure that can be applied with drag technology is limited, but this limitation is logical. Higher pressures are typically reserved for thicker and harder media. However, when it comes to cutting such rigid substrates, the drag knife technology isn't as well-suited compared to other cutting methods.

DRAG KNIFE TECHNIQUE ADVANTAGES:

espite its limitations, drag knife technology remains a prevalent and influential cutting method. This fact is evident in the widespread acclaim of the S One series, which stands as one of the most sought-after vinyl cutter ranges ever created.

Featuring advanced technology, including a high-speed cutting head, impeccable tracking, and an optical positioning system, the S One series delivers exceptional performance at a remarkably affordable price point. Experience the reliability and ease of vinyl cutting with the Summa S One series, where quality meets affordability.

TANGENTIAL:

HOW DOES TANGENTIAL KNIFE TECHNOLOGY WORK?:

In addressing the constraints of drag knife technology and catering to the unique requirements of users, Summa has introduced tangential knife technology. Unlike the drag knife's freely rotating mechanism, the tangential knife is equipped with a motor for precise control. This external motor ensures that the knife is accurately positioned at the correct angle.

Unlike the drag knife, which stays in contact with the media throughout the cutting process, the tangential technology lifts the knife from the media, rotates it, and then lowers it back into the media, enhancing precision and versatility.

HOW DOES TANGENTIAL RESPOND TO MEDIA?:

Utilising tangential knife technology yields impeccably shaped corners, regardless of whether you're working with thin or thick, rigid media. Unlike drag knife technology, tangential cutting isn't influenced by drag forces, ensuring precise trajectory. This technology enables significantly higher cutting pressures and accommodates the use of longer knives compared to drag knife systems. Consequently, users can achieve detailed, high-quality cuts in thicker and harder substrates, mirroring the precision of cuts in thinner materials.

Primarily employed in flatbed cutting machines designed for thick substrates, tangential knife technology finds its place in various applications including floor graphics, vehicle graphics, textiles, sandblasting, road and safety signs, and more. For superior cut quality across diverse substrates, we highly recommend utilizing a cutting machine equipped with tangential knife technology.

WHAT ARE THE ADVANTAGES?:

One of the standout advantages of Summa's knife technology is its precise depth control, often overlooked by many. While tangential cutting technology is commonly associated with processing thick substrates, Summa's implementation allows operators to finely adjust cutting depth with astonishing accuracy, down to the thickness of a human hair.

Another notable benefit lies in the ease of weeding out vinyl parts. Thanks to the perfectly shaped corners achieved through the overcut feature, removing excess material becomes effortless. Even cutting intricate details in heavily laminated media is simplified to a task akin to child's play. Furthermore, Summa's FlexCut feature enhances versatility by facilitating perforations and tear-off lines with unmatched reliability on tangential machines.

With minimal restrictions and boundless possibilities, you can seamlessly integrate these functions into your projects, expanding creative horizons.

-

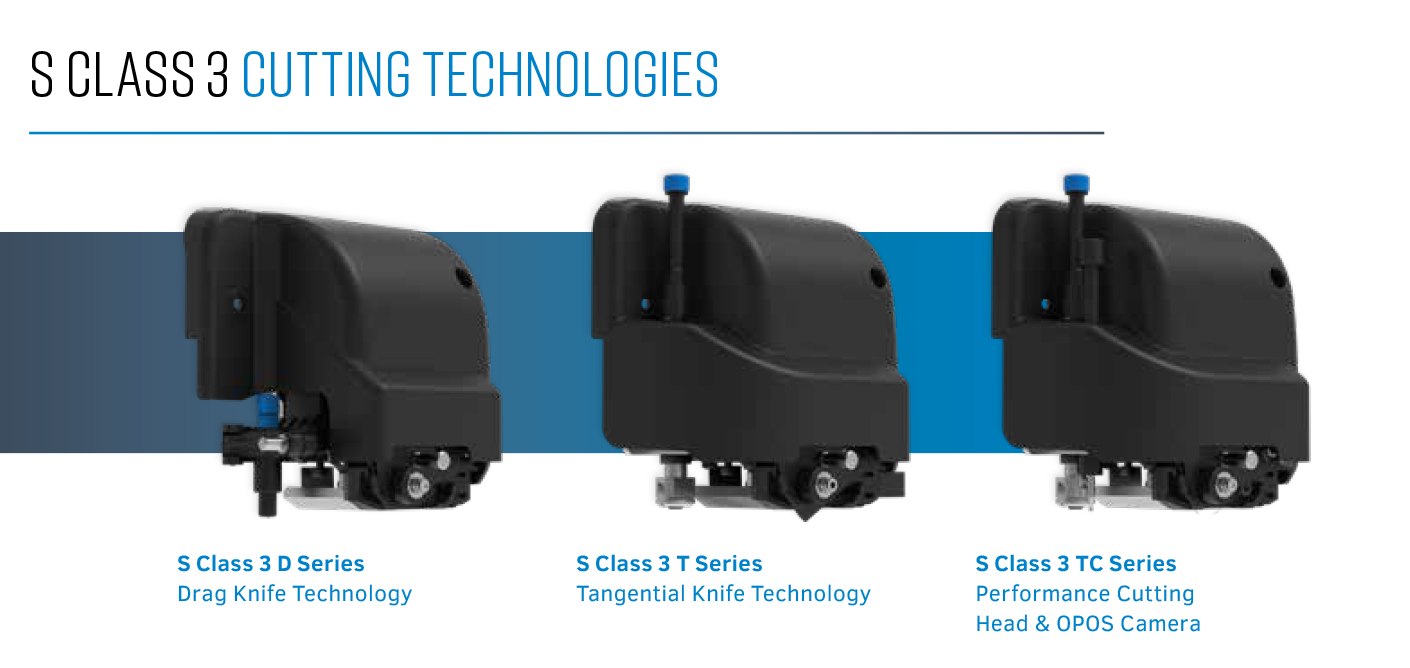

Cutting Technologies

D SERIES:

The Summa S3 D Series roll cutters are engineered with high-volume cutting environments in mind. These machines seamlessly combine the renowned power and precision of the S Class with an efficient and cost-effective drag knife cutting head. Packed with a plethora of industry-first innovations and inherent capabilities, the S3 D Series stands as a versatile powerhouse, capable of tackling diverse tasks with resilience and reliability, day in and day out.

T SERIES:

The Summa S Class 3 T Series combines the formidable power and precision of the S Class with the cutting-edge True Tangential cutting head. With an impressive suite of innovations and integrated features, this cutter sets the benchmark for excellence in roll cutting, ensuring unmatched performance and precision for your projects.

TC SERIES:

The TC models within the Roll Cutter Series are outfitted with the pinnacle of cutting head technology. This advanced cutting head boasts unparalleled precision and versatility, accommodating two tools simultaneously.

This means you can seamlessly combine FlexCut and kiss-cutting with creasing or drawing, all without the need to switch tools. It's a game-changer for efficiency and flexibility in your cutting processes.

Download a Brochure

-

Summa S Class 3 S160 T-Series 63” 1600mm Cutter S3T160 - DATA SHEET

Download