- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Bricsys BricsCAD® Software

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

UltiMaker METHOD Speciality Material Black PETG (375-0029A)

-

Description

UltiMaker METHOD Speciality Material Black PETG (375-0029A):

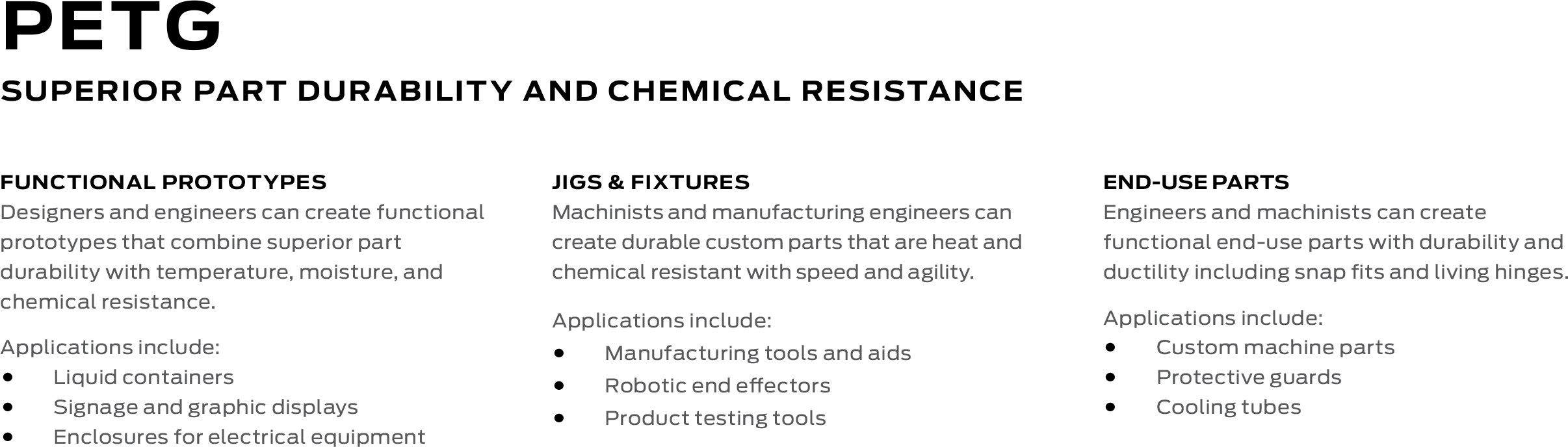

Combines the qualities of PLA and ABS filament PETG (Polyethylene Terephthalate Glycol) and is becoming increasingly popular as the material of choice for printing high-performance parts requiring excellent durability along with temperature, moisture, chemical resistance and flexibility. Engineers and designers use Speciality PETG to produce durable prints with speed and agility that can withstand industrial applications including functional prototypes, jigs and fixtures, and end-use parts.

UltiMaker METHOD PETG Speciality Material is designed for use with the Method 3D Printer. For best results, the material should be used with an adhesive on the build plate.

If using with the METHOD X standard Method extruders may be required, please check with us for details.

FEATURES:

- Excellent mechanical properties, including high durability and toughness: 8.1 kJ/m2 Impact Strength (ISO 179)

- Higher heat resistance than both PLA and Tough: 70C Heat Deflection Temperature (ASTM 648) Chemical resistance to acidic and alkali compounds

- Moisture Resistant: 1104 ppm moisture absorption (ISO 62)

- Prints with water-soluble PVA supports

- Final parts have good ductility and a glossy surface finish

- Easily combine the new PETG material with water-soluble PVA supports thanks to the 3D printer’s dual extruders

SPECIALTY MATERIAL USER NOTE:

Speciality Materials provide basic print performance and can require additional workflow steps to print successfully. PETG requires the application of adhesion stick to the build plate prior to printing.

STORAGE ENVIRONMENT:

Store in the included a vacuum-sealed metalized polyester bag to avoid moisture absorption from air; long-term exposure to humidity can compromise material quality and performance. Make sure the built-in desiccant is in the spool to absorb any moisture exposure during the material loading process.

MATERIAL DATA:

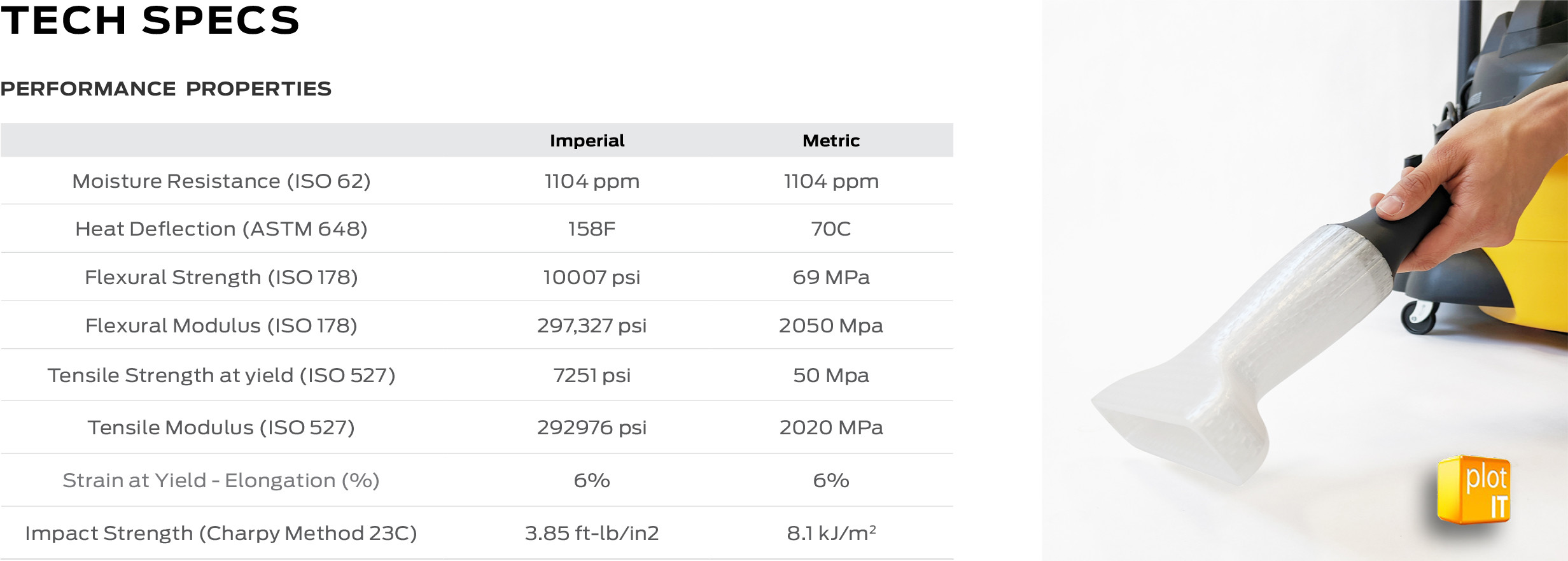

Moisture Resistance (ISO 62): 1104 ppm

Heat Deflection - ASTM 648: 70°C (158°F)

Flexural Strength (ISO 178): 69 MPa (10007 psi)

Flexural Modulus (ISO 178): 2050 Mpa (297,327 psi)

Tensile Strength at yield (ISO 527): 50 Mpa (7251 psi)

Tensile Modulus (ISO 527): 2020 MPa (292976 psi)

Strain at Yield - Elongation (%): 6%

Impact Strength (Charpy method 23C): 8.1 kJ/m² (3.85 ft-lb/in²)

-

Other available colours

-

Technical Data

Download a Brochure

-

UltiMaker METHOD Speciality Material Black PETG (375-0029A) Brochure

Download