- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Autodesk Subscription & HP CAD Workstations

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

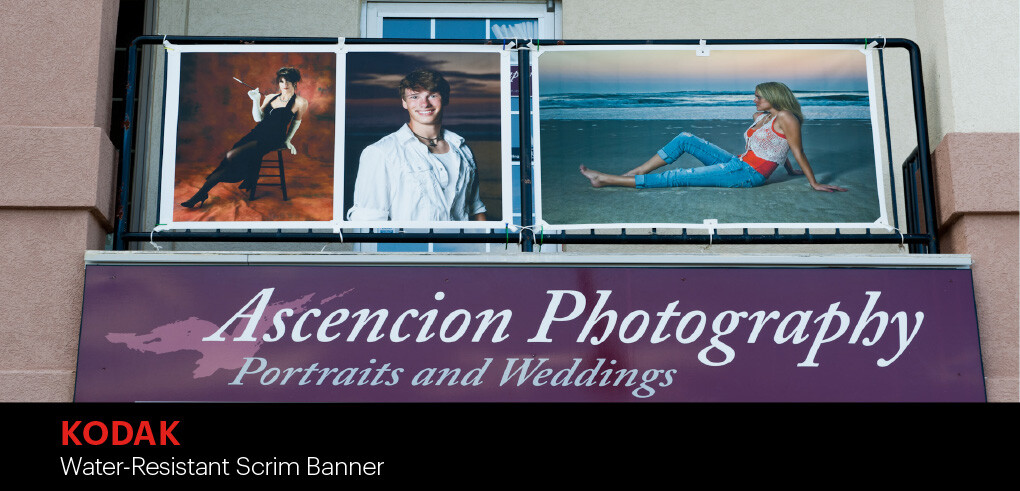

Kodak KWRSB36 Water-Resistant Scrim Banner 16 mil 450g/mē 36" 914mm x 12.2m roll

-

Description

Kodak Water-Resistant Scrim Banner 16 mil 450g/m²:

Inexpensive Scrim reinforced Banner for Aqueous Inkjet devices such as Canon imagePROGRAF, EPSON Surecolor and DesignJet Z series Printers. These short lengh12m rolls milled on 2” cores are designed to fit the majority of printer models mentioned and are ideal for when robust indoor and outdoor advertising is required without the need of a solvent or latex printer.

When used with Aqueous Pigment inks there is a high level of water resistance, high scratch resilience and the media features a High Bright White Point.

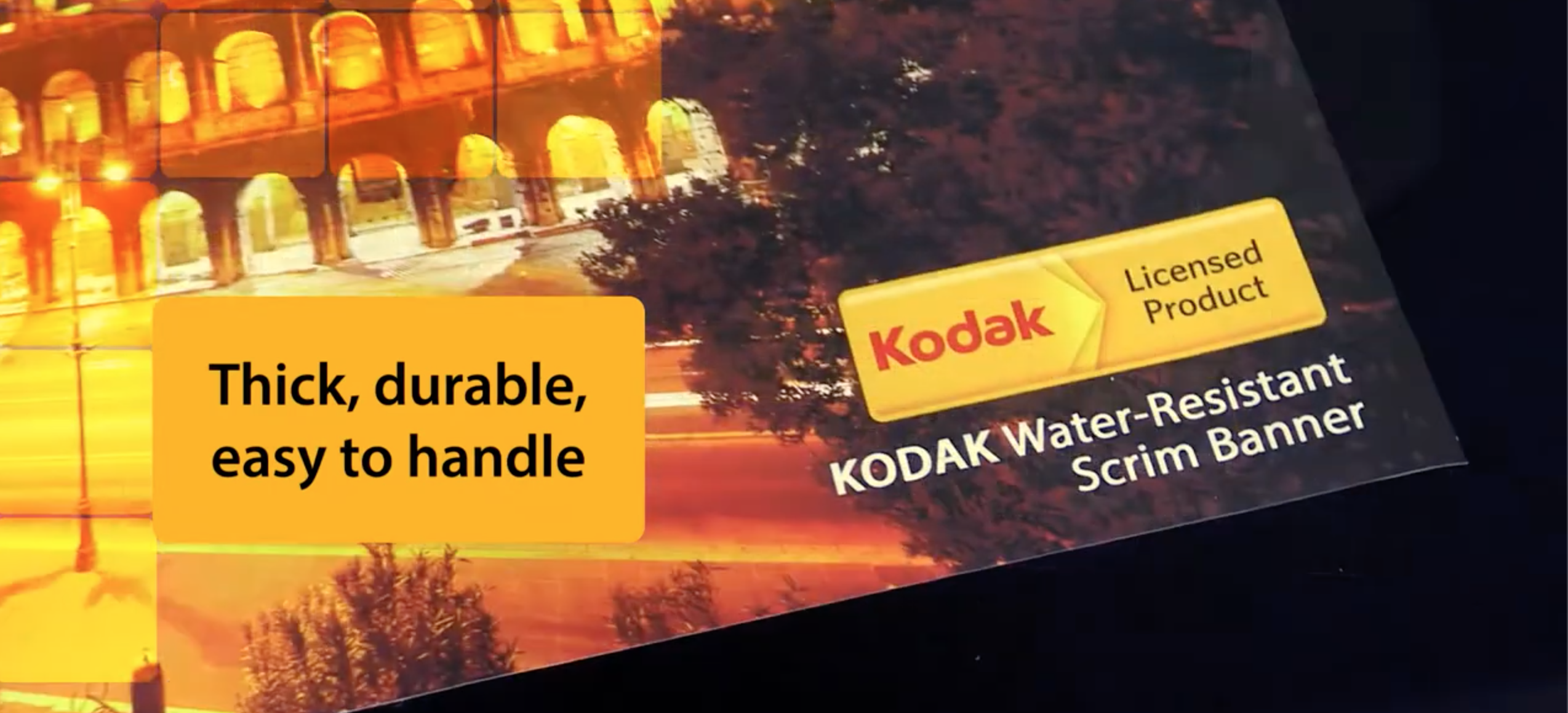

The Kodak Water-Resistant Scrim Banner is a durable, 16-mil thick vinyl material reinforced with a scrim (a strong, open-weave fabric). This design is intended for producing high-impact and long-lasting graphics.

KEY FEATURES:

- DURABILITY: The scrim reinforcement provides enhanced durability, making the banner resistant to water and suitable for various weather conditions.

- EFFICIENCY IN PRODUCTION: The material is designed for easier handling during production, which can lead to increased efficiency and the ability to handle high-volume banner jobs effectively.

- COST-EFFECTIVENESS: By combining durability with cost-effectiveness, the scrim banner allows users to produce high-quality graphics economically.

- PRINTING COMPATIBILITY: The banner is compatible with both thermal and piezo printing technologies, offering versatility in production methods.

APPLICATIONS:

- Long-term Indoor Banners

- Short-term Outdoor Banners

-

Other available sizes

Kodak | KWRSB24 | Water-Resistant Scrim Banner 16 mil 450g/m² | 24" 610mm x 12.2m roll (2" core)

Kodak | KWRSB36 | Water-Resistant Scrim Banner 16 mil 450g/m² | 36" 914mm x 12.2m roll (2" core)

-

Properties

PROPERTIES SPECIFICATIONS MATERIAL Tear-resistant polyester fabric embedded between two white vinyl layers

GAUGE 16 mil

WEIGHT 450 g/m2

OPACITY >95

WHITENESS ≥ 130 (CIE)

PRINTER/INK COMPATIBILITY Compatible with all thermal and piezo inkjet printers using water-based dye and pigmented-based inks.

SOFTWARE SETTING When using this material with Encad GO inks, utilize the UCR (Under Colour Removal) technique that replaces composite black (CMY) with the appropriate amount of black ink. To optimise print quality, printers should be set for the highest print quality and media selection should be set on “heavy coated.” Ink coverage up to 250% is recommended.

COLOUR MATCHING For the best and most consistent results, a profile should be created using an external color calibrator in con- junction with your RIP and color matching software.

LIGHTFASTNESS The fading time of inkjet ink is a direct result of the inks that you choose to use and the environment where the print is displayed. All dye-based inks fade noticeably under direct sunlight, in interior applications where direct sunlight may fall on an image, and/or where fluorescent or other UV lighting is present. Although the fading process is inherent with all inkjet inks, certain UV enhanced inks, pigment-based inks, and UV inhibiting laminates will extend the longevity of an image. Contact the ink manufacturer to determine suitability for a particular application.

COLOUR L* = 89 - 92, a* = 4.0 ± 2.0, b* = -12.0 ± 3.0

FINISHING/POST PROCESSING Pressure sensitive vinyl laminates with UV inhibitors can be applied to increase the fade and abrasion resis- tance of the image. Polyester or other base material laminates are not recommended. Before applying the laminate, allow the image to dry for 24 hours.

Download a Brochure

-

Kodak KWRSB36 Water-Resistant Scrim Banner 16 mil 450g/mē 36" 914mm x 12.2m roll - DATA SHEET

Download