- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Bricsys BricsCAD® Software

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

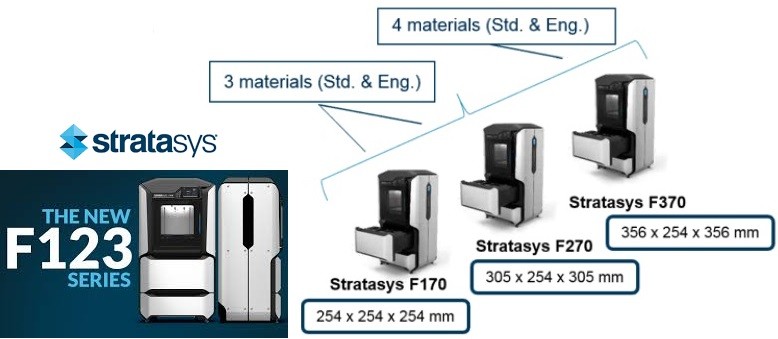

Stratasys F370 3D Printer

-

Please contact us on 01905 454 598 for a quote

-

Description

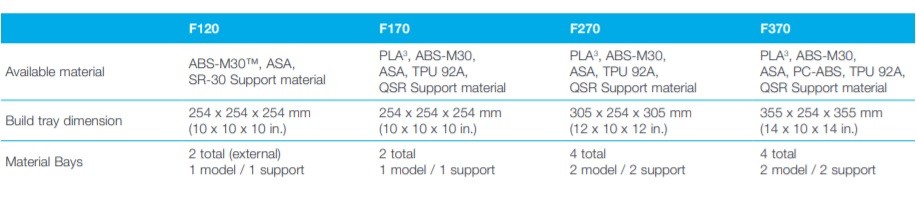

The Stratasys F370 features a build bay which is 96% larger than the entry level F170 and 36% bigger than the F270.

With it's stylish design thanks to a combination of BMW Design Works and the Stratasys Design team the F370 features 2 easy to access material bays and 2 support material bays.

Front loading media makes user life easy with everything accesible from the front of the machine.

Stratasys F370 3D Printer lets you print everything from fast, low-cost concept models to durable assemblies and offers users the choice of low cost PLA, ABS, ASA and in addition PC-ABS which is not available with the F170 or F270 Models.

F370 - Maximum Build Size (XYZ) 355 x 254 x 355 mm (14 x 10 x 14 in)

The all-in-one power of the Stratasys F123 series gives you value all around — with expanded capabilities and unprecedented accessibility.

The all-in-one power of the Stratasys F123 series gives you value all around — with expanded capabilities and unprecedented accessibility.New and improved features save time and material. Incredible ease of use with both the hardware and the software means you don’t need special 3D printing expertise.

The F370 in addition to Grabcad also comes with Stratasys Powerful insight software

Super quiet and office friendly. Reliable, consistent printing ensures less waste.

-

Stratasys F370 materials

The Stratasys F370 offers more filament materials than any other F123 Series 3D Printer through it's standard extrusion head and optional print heads

PLA | E C O N O M Y T H E R M O P L A S T I C

PLA is a renewable plastic material offered as a low-cost material option for fast-draft part iterations. PLA offers a higher stiffness than ABS and its low melting point and HDT mean less heat & power required to print parts. Utilises Breakaway and not soluble support. PLA Extrusion Head & cooler required.

TPU | ELASTOMER T H E R M O P L A S T I C POLYURETHANE

FDM TPU 92A brings the benefits of elastomers to FDM 3D printing and offers the capability to quickly produce large and complex elastomer parts. Typical applications include flexible hoses, tubes, air ducts, seals, protective covers & vibration dampeners.

TPU Elastomer Extrusion Kit required

ASA | U V- S TA B L E , P R O D U C T I O N - G R A D E T H E R M O P L A S T I C

Build consistently high-quality parts, with exceptional UV stability and the best aesthetics of any FDM® thermoplastic. ASA is avialable in a wide selection of colours and it's matte finish makes it ideal for attractive prototypes. Matching or exceeding the mechanical properties of ABS, ASA may be your new favorite general prototyping material also it's UV-resistance makes it especially suited for production parts. Works with standard supplied head.

ABS-M30 | P R O D U C T I O N - G R A D E T H E R M O P L A S T I C

ABS-M30 parts are stronger, smoother and have better feature detail. At up to 25 to 70 percent stronger than standard ABS and is an ideal material for conceptual modelling, functional prototyping, manufacturing tools and production parts. With greater tensile, impact and flexural strength than standard ABS. Layer bonding is significantly stronger than that of standard ABS, for a more durable part. This results in more realistic functional tests and higher quality parts for end use.

PC-ABS | P R O D U C T I O N - G R A D E T H E R M O P L A S T I C

Only avilable on the F370 3D Printer PC-ABS (polycarbonate-ABS) is one of the most widely used industrial thermoplastics. PC-ABS offers the most desirable properties of both materials – the superior strength and heat resistance of PC and the flexibility of ABS. PC-ABS blends are commonly used in automotive, electronics & telecom applications. Additionally, a PC-ABS part manufactured on a Stratasys F370™ 3D Printer is 5-60 percent stronger than a part made on previous FDM® systems. PC-ABS gives you conceptual modelling, functional prototyping, manufacturing tools and production parts.