- CAD Plotters

- Wide-Format Photo, Fine Art & Graphic Printers

- HP Latex, Outdoor, Signage, Wall Paper Printers & Cutters

- Wide Format Ink & Media Supplies

- Multi Functional Printers & Plan Copiers

- Large Format Scanners

- Finishing - Large Format Paper Folders, Trimmers, XY Cutters & Laminating

- Canon A4 and A3 Copier Paper

- Canvas, Stretcher Bars & Laminate

- Fabric Printers

- 3D Printers

- Bricsys BricsCAD® Software

- Colour Management & RIP Software

- Plotter Warranties

- Storage & Filing Systems

- OFFERS

Why use plot-IT?

- Est since 1965

- Group turnover - £15 million

- 5 UK offices with over 100 staff

- HP Designjet Warranty Provider

- Autodesk Gold reseller

- Canon Elite Partner

- Stratasys - Gold Partner

UltiMaker Method X Standalone SR-30 Support Extruder 2XA 900-0044A

-

Please contact us on 01905 454 598 for a quote

-

Description

UltiMaker Method X Standalone SR30 Support Extruder 2XA 900-0044A:

The Support 2XA Performance Extruder is optimised for high speed and accurate printing using SR-30 soluble support materials to accompany model materials like ABS and ASA. Featuring a 0.4mm diameter nozzle delivering 200 Newtons of torque with a 19:1 dural-drive gear ratio, with smart sensors that detect temperature, materials, and jamming to protect your print. The lengthened thermal core helps to ensure a one-minute heat up time. The extruder has a quick-release locking mount for stable printing and quick swapability. To view to full range of MakerBot filaments please click here.

SR-30 is a proprietary material developed by Stratasys to work seamlessly with ABS, ASA, and various other high-temp materials. Because of this focused development, using SR-30 with these typically more challenging materials can yield exceptional results not possible with PVA which is very difficult to use with ABS.

Compared to water soluble PVA, SR-30 requires additional products to aid dissolution. STRATASYS Ecoworks Cleaning Agent 2SSY680 tablets are designed to remove support material from parts manufactured using the FDM process. These tablets are user- and eco-friendly requiring no gloves of special disposal requirements.

The Stratasys SCA 1200HDT Support Cleaning Tank is designed to dissolve support material from 3D models created on any of the Stratasys & Makerbot Method X 3D Printers that use Soluble Support Technology. A versatile system offers temperature choices that readily clean supports from all the SST-compatible materials ABS, PC, and nylon. The SCA-1200 basket can hold parts up to 254 x 254 x 304.8 mm and can therefore clean a single large part, or multiple smaller parts in its tank saving time when multiple parts require cleaning.

FEATURES:

- SMART SENSORS FOR MATERIAL MANAGEMENT & PRINT PROTECTION: The Performance Extruder contains a suite of sensors that detect when material is running low & allows for active jam detection during the entire print duration.

- GREATER TORQUE WITH A 19:1 DUAL-DRIVE GEAR RATIO: A 19:1 dual-drive gear ratio keeps material loaded and ready for reliable material extrusion at every layer.

- LENGTHENED THERMAL CORE LESS THAN 60 SECONDS HEAT UP TIME: A lengthened thermal core and a fast start up time ensure that materials are ready to go when your ideas are.

- QUICK-RELEASE LOCKING EXTRUDER MOUNT: For high stability printing and easy swapping.

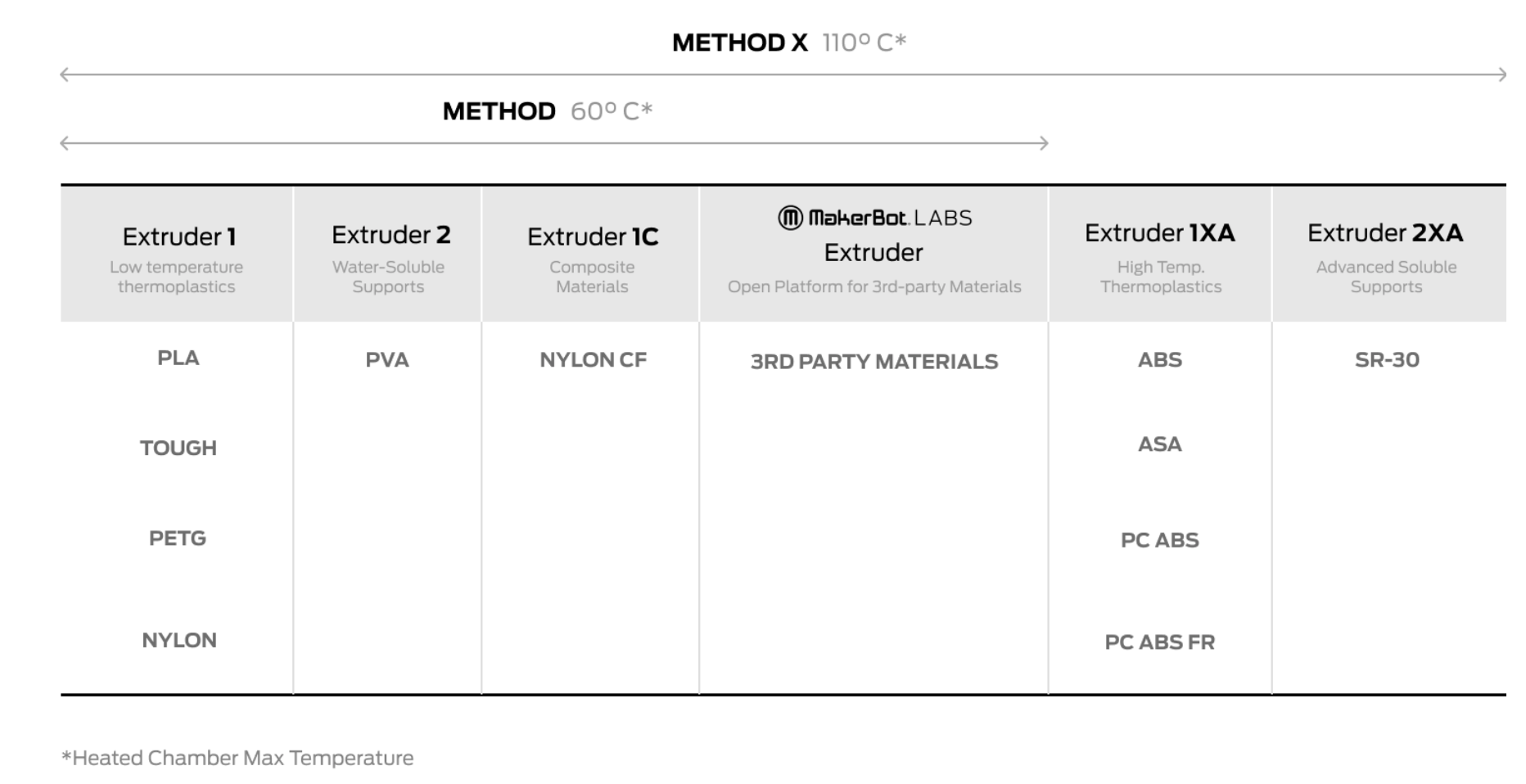

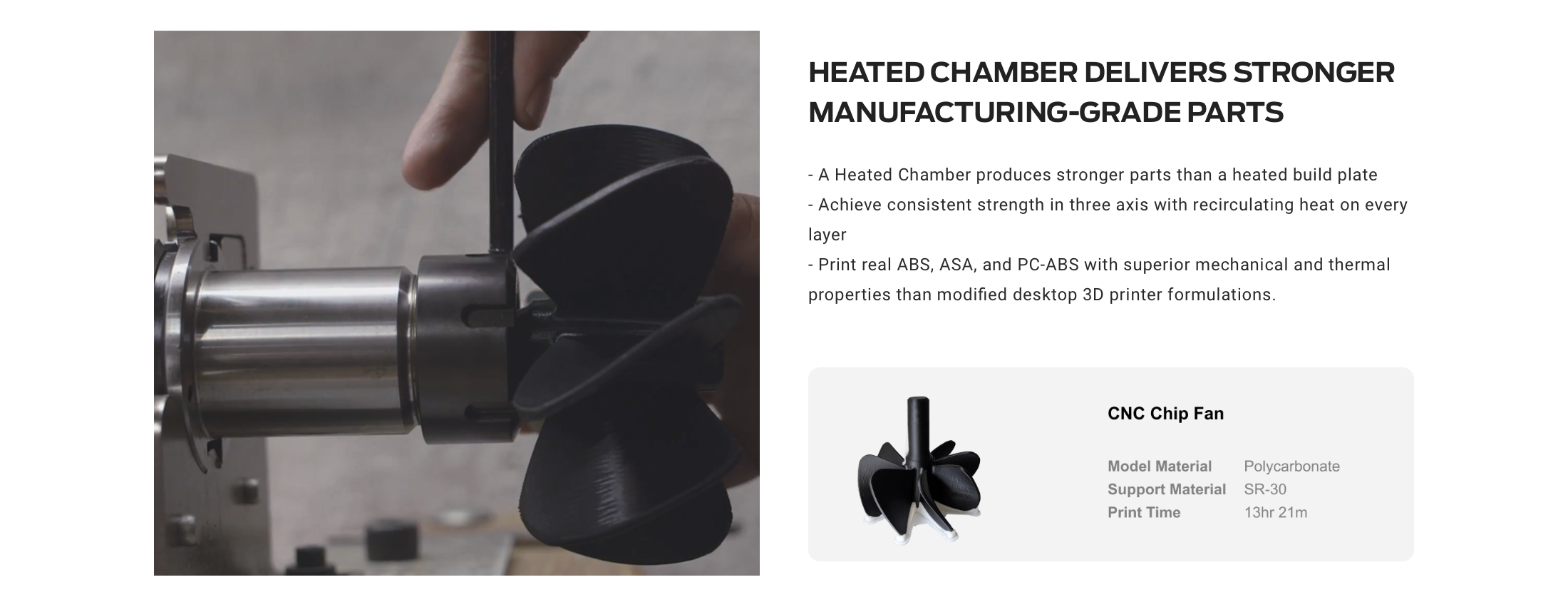

Compatible with METHOD X and METHOD X CARBON FIBER EDITION 3D Printers.Print real, production-grade ABS at 100°C with no warping or cracking supported by Stratasys® SR-30 soluble material for unlimited geometric freedom. UltiMaker ABS for METHOD is capable of withstanding 15°C higher temperatures, is 26% more rigid, and 12% stronger than modified ABS material formulations for alternative desktop 3D printers - features normally associated with industrial 3D, offering uncompromised Layer adhesion & part strength thanks to the Circulating Heated Chamber developed using Patented Stratasys technology which bridges the gap between industrial & Desktop 3D Printing.Control the temperature and quality of every layer - not just the first. While heated build plates are effective at reducing warping, Method takes this further with full active heat immersion during the entire duration of the print.

Optimised Material Storage

Optimised Material StorageDry-Sealed Material Bays form a near-perfect seal to keep material free of damaging humidity. A suite of built-in sensors provides that your material is stored in its optimal environment.

Smart Spool provides valuable information including material type, colour & amount remaining via RFID chip directly to MakerBot Print, while a built-in desiccant absorbs any moisture exposure during the material loading process. In addition to ABS you can also utilise all the standard METHOD materials......

Download a Brochure

-

UltiMaker Method X Standalone SR-30 Support Extruder 2XA 900-0044A - DATA SHEET

Download